Thermoforming

Thermoforming of plastics

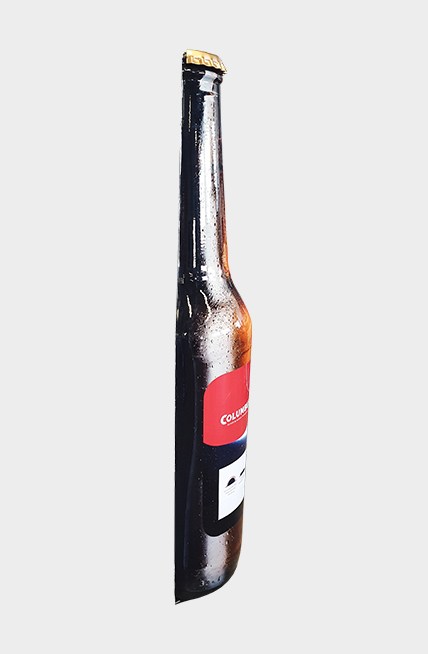

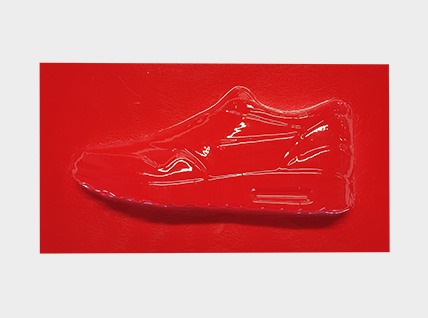

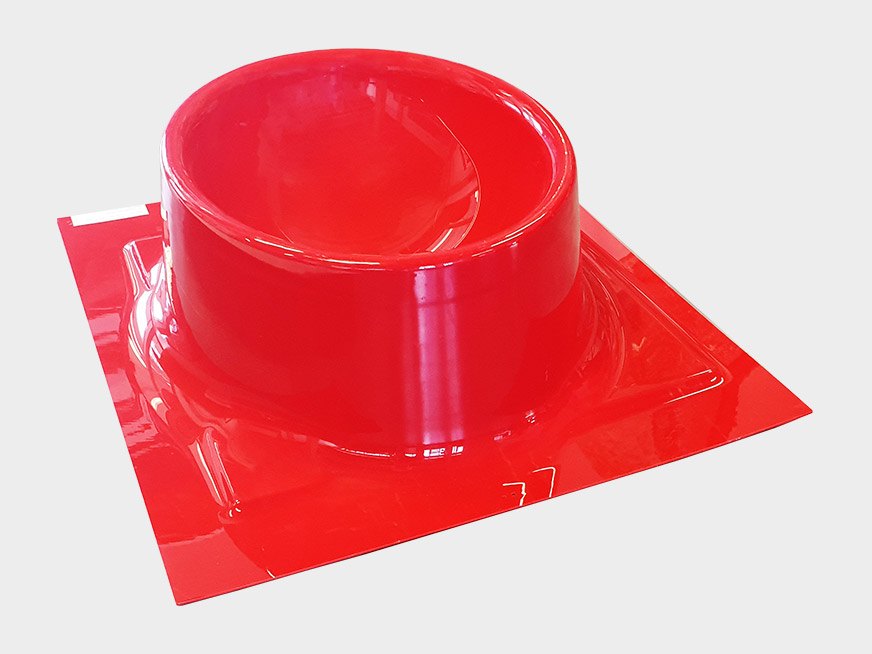

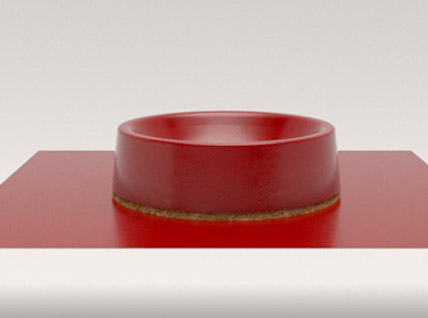

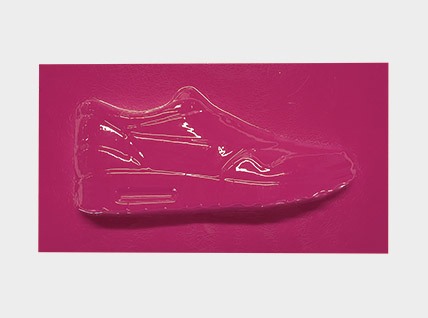

Columbus defines thermoforming as an application process, in which a thermoform-able, usually thin-walled plastic gets clamped into the frame, instead of the membrane, and then, in a second step, — with the force of vacuum and the use of constant heat treatment, which puts the plastic in a foil-like state — gets pulled over a template. After curing the plastic retains in the shape of the template.

Das Video kann leider nicht abgespielt werden!

Sie können das Video aber über folgenden Link herunterladen:

Sie können das Video aber über folgenden Link herunterladen:

Download Video

Fields of application:

Prototype construction

Merchandising products

Vehicle construction

Lamp production

Container construction

Packaging production

Casings Cladding production

Examples of materials:

ABS

PMMA

PET-G

PS

PVC-U

EPVC

PP

PPE

TPO

Brands:

Plexiglas

Acrylglas

Lucite

Viva

Makrolon

Your benefits:

- Extension of the own product range, expansion of the target audience and increase in sales.

- High productivity increase and process acceleration through flexible prototyping without set-up times.

- The possibility of wage work for other companies due to the service extension.

- Cost reduction through more economical use of materials due to adjustable forming frames.

- Safety in production through the use of a high-quality and proven system.