- Extension of the own product range, expansion of the target audience and increase in sales, through the fast production of laminated bending, shape bonding and flat gluing work pieces.

- Time, material and cost savings due to the ability to produce shape bonding work pieces without using a counter-stencil.

- Shortening of production times, acceleration of the whole production process and increase of productivity of the entire company.

- Perfect press results due to the even distribution of the atmospheric pressure, which results in the production of high-quality workpieces.

- A higher contribution margin due to the independence of external suppliers.

variety of applications

variety of applications

Discover

the incredible variety of applications of a Columbus vacuum press or

a Columbus vacuum bag and thereby significantly expand your

opportunities in the production process. In the detail information of

the respective application you will find much more useful information

about the workflow, the possible areas of application as well as the

compatible materials and material brands.

Experience the variety

of possibilities

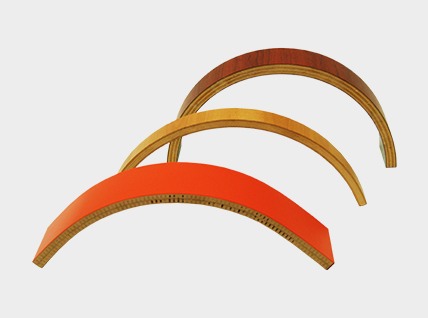

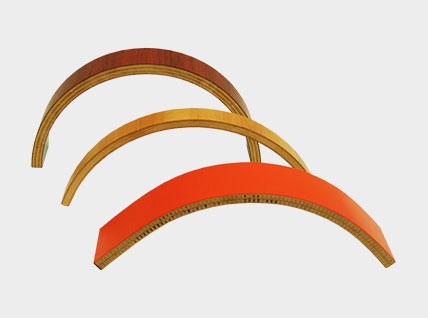

The innovative vacuum press technology from Columbus offers numerous

application possibilities. Due to this diversity, there are no limits to

your own creativity. Thus, specialized companies are able to meet even

the most special customer requirements. The following impressions

illustrate the incredible variety of applications that can be achieved

with Columbus vacuum presses.

Acoustic and sound insulation systems

Vehicle construction (e.g. campers and airplanes)

Store construction

Prototype construction for the industry

Toys

Stage construction and exhibition construction

Store facilities

Modelling

Restoration (e.g. vintage car)

Sports equipment

Exclusive interior

Interior of yachts and ships

Musical instruments

Coffin production

Merchandising products

Realize

your visions

with us

your visions

with us

IMPORTANT: We respond to every inquiry promptly. If you don't hear from us, please check your spam folder or contact us!

Request offer

We will be happy to make you an offer exactly for your individual needs!

Herzlichen Dank für Ihre Anfrage!

Wir werden uns umgehend mit Ihnen in Verbindung setzen.

Wir werden uns umgehend mit Ihnen in Verbindung setzen.