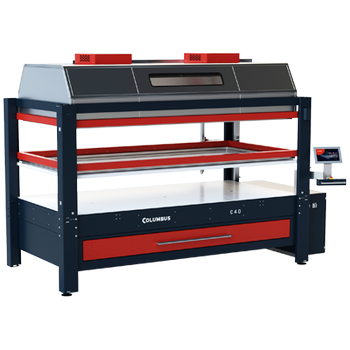

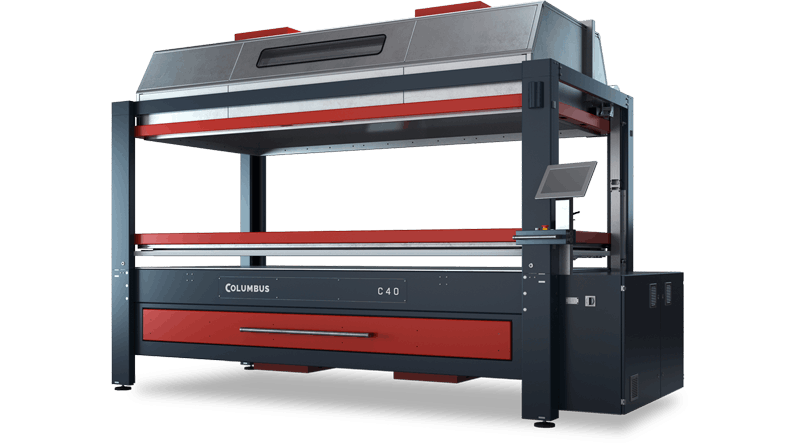

The C40 Industrial has a gigantic usable area on which even very large workpieces can be easily processed. Highest engineering skills, in the development of the working surface, guarantee unprecedented precision. The robust construction makes the C40 Industrial absolutely torsionally rigid. This uncompromising approach guarantees enormous variety in terms of product range and high reliability of results.

C40 Industrial

The next generation vacuum press

C40 Industrial

The next generation

vacuum press

The C40 Industrial is the ideal vacuum press for innovative production plants on an industrial level. It was created with more than 40 years of hands-on experience and technology leadership, built for people who are already developing the innovations of tomorrow today and produced to be one step ahead of the competition at any time.

This high-tech vacuum press offers all the applications of vacuum press technology — from laminated bending over the forming of plastics to thermoforming — and takes the workflow to a whole new level with technical finesse. State-of-the-art components create a symphony of ultimate performance and perfected efficiency.

In short, with the C40 Industrial, the vacuum press has been completely reinvented and perfected to the ultimate tool for those companies who want to create great things, excite their customers, and sustainably increase their sales.

This high-tech vacuum press offers all the applications of vacuum press technology — from laminated bending over the forming of plastics to thermoforming — and takes the workflow to a whole new level with technical finesse. State-of-the-art components create a symphony of ultimate performance and perfected efficiency.

In short, with the C40 Industrial, the vacuum press has been completely reinvented and perfected to the ultimate tool for those companies who want to create great things, excite their customers, and sustainably increase their sales.

This makes the C40 IndustrIAL

the quantum leap in

vacuum press technology

1 / 13

The gigantic precision vacuum table

2 / 13

The power efficiency principle

The power efficiency principle of the C40 Industrial embodies absolute efficiency enhancement and power maximization. Care was taken to use only energy-saving components with simultaneously optimized resource utilization. The perfected hermetics of the system simultaneously guarantees loss-free working. Precise heat control, optimal heat distribution and outstanding thermal insulation ensure the efficient use of energy. The C40 Industrial achieves maximum power with minimal resource consumption.

3 / 13

The electromechanical precision drive

The vertical opening mechanism was perfected by an electromechanical precision drive. Thanks to the significantly optimized technology, absolutely linear press drives and precise stopping in the desired position are now possible. The exactly and infinitely adjustable parallel opening as well as the linear drives, equipped with automatic stop, guarantee unprecedented application and result reliability.

4 / 13

The patented integrated vacuum storage system

The patented, integrated vacuum storage system for extremely fast vacuum build-up is a world first you only get with the C40 Industrial. Where conventional vacuum presses still work with an external vacuum tank, the C40 Industrial offers a generous vacuum reservoir, which is already built into the design. Due to the extremely compact design, achieved in this way, the C40 Industrial finds its place in every production plant. In addition, the vacuum storage system offers increased capacity and optimized speeds during vacuum build-up.

5 / 13

The uncompromising hermetic principle

The vacuum system of the C40 Industrial, which was developed according to the hermetic principle, is 100 % leakproof. Once the vacuum has been built up, it will be retained, over a very long period of time. This saves precious energy and valuable time. This unique result is due to a re-imagined line and connection system. Nearly seamless connectors and permanently integrated components hold the vacuum firmly in the system and guarantee loss-free working. The C40 Industrial makes no compromises in this regard.

6 / 13

The controlled circulating air heating system

The controlled circulating air heating system of the C40 Industrial sets new standards in terms of heat distribution and thermal insulation. A precisely controlled hot air flow, in the heating drawer and the heating hood, guarantees an exact temperature distribution and faster heating processes. Due to that, a uniform heating of the workpiece is achieved. Temperature differences at different parts of the workpiece are a thing of the past. This reduces reject rates, minimizes material consumption and guarantees best results in the forming process.

7 / 13

The fully automatic vacuum valve

With conventional vacuum presses, the vacuum build-up or release must be controlled manually with a ball valve. The C40 Industrial can control all this automatically for the first time now. When commanded via the control panel, the optional fully automatic vacuum valve controls vacuum build-up or release without the need for manual intervention. This perfects the workflow in terms of efficiency, speed and operation safety.

8 / 13

The highly precise heating control

A high-precision control electronics, coupled with the efficient heat insulation of the heating system, ensures accurate temperature control and uncompromising consistency. This allows even the most sensitive materials to be heated to optimum conditions and then formed into extraordinary workpieces.This high-end system leaves nothing to chance, regarding heat supply, and guarantees absolute certainty of results and freedom of creation.

9 / 13

The thermal separation

The new heating systems of the C40 Industrial achieve unprecedented thermal insulation performance. Because the revolutionary two-shell construction guarantees absolute thermal separation. This means that the heat is effectively kept in the heating hood or the heating drawer, but the outer shell remains unaffected. The system prevents heat waste and hot outer surfaces. This provides even more operation security, without the risk of burns and a significant increase in energy efficiency. Another advantage of this is that the machine never warps, even with extreme temperature fluctuations.

10 / 13

The „touch-soft-close“ function

The feeding system of the heating drawer was completely redeveloped with the C40 Industrial. The extremely robust heating drawer, with the touch-soft-close function, offers now a gentle closing mechanism, as it is known from drawers in the kitchen. This guarantees absolute operation safety. Thanks to the locking mechanism, the opening and closing of clamping locks are a thing of the past. The result is an even more efficient workflow

11 / 13

The next-generation automatic program

With the next-generation automatic program, processes or work steps can be automated and, as a consequence, the overall efficiency of the production operation can be increased. For that the pre-installed programs for pressing, heating, wrapping or thermoforming can be used. If certain work steps are used more frequently in a production plant, a new program sequence can also be conveniently created and stored to automate the process. This can later be retrieved as often as one like. The intuitive operation makes the training of new employees or the use of the system extremely easy.

12 / 13

The universal frame carrier

The C40 has only one universal frame carrier. On the universal frame carrier, both, the membrane frame, with integrated membrane fast-change system, as well as the foil frame or deep drawing frame, can be mounted. In other words, one frame for everything. If you want to change over quickly, the universal frame carrier makes it easy to install the required frame.

13 / 13

The digital machine management

The C40 Industrial offers the most advanced and comprehensive machine management of the entire vacuum press technology. All control and monitoring processes are completely digitized and are made available to the user via a touch-screen monitor via an intuitive user interface. High-tech hardware and software make it possible to perform even the most complex processes completely individually and very easily. With the C40 Industrial you keep all parameters perfectly in view. The data, accurately recorded by the system, can be archived and exported at any time for quality assurance purposes. In addition, the C40 Industrial is internet-enabled. With the integrated remote maintenance mode, it is possible to carry out worldwide troubleshooting or updates from Columbus.

That is what C40 Industrial can do

Depending on the configuration, C40 allows you to perform the

following applications. You will find many other useful information

about the workflow, the possible fields of application as well as the

compatible materials and material brands in the detailed information of

the respective application.

Key-Features

Unique.

Advanced.

Safe investment.

Years of development and high engineering skills "Made in Austria" make the C40 an absolute quantum leap in vacuum press technology. State-of-the-art technology, highest efficiency and ultimate performance make it the ideal vacuum press for advanced production plants on an industrial level.

Key-Features

An invisible

highlight.

Conventional vacuum presses have bulky, external vacuum tanks. During the development of the C40 everything possible was done to create an innovation that unfolds its power in secret. After all, with the integrated vacuum storage system, available as a factory option, the C40 offers a modern system that quickly builds up the vacuum and stores it for weeks without loss. And that — compared to conventional vacuum presses — with a significantly increased storage volume.

Key-Features

More power.

Less energy consumption.

Less energy consumption.

The C40 Industrial was designed according to the power-efficiency principle: minimizing energy consumption and maximizing power. Perfected hermetics, outstanding insulation, efficient components — the key factors in generating maximum power with minimal resource consumption.

Key-Features

Because 171° Celsius is not enough,

if you want 172 ° Celsius.

A high-precision control electronics, coupled with highly efficient thermal insulation, ensures a degree-accurate temperature control and uncompromising consistency. For optimized forming processes, even for the most demanding materials. This means the highest possible reliability of results in all forming processes.

Experience the variety

of possibilities

The C40 Industrial gives you the opportunity to perform multiple profitable

applications. Due to this diversity, there are no limits to your own

creativity and you can extend your product range and increase your sales

with every new idea. The following impressions illustrate the

incredible application variety of C40 Industrial.

Features and technical data

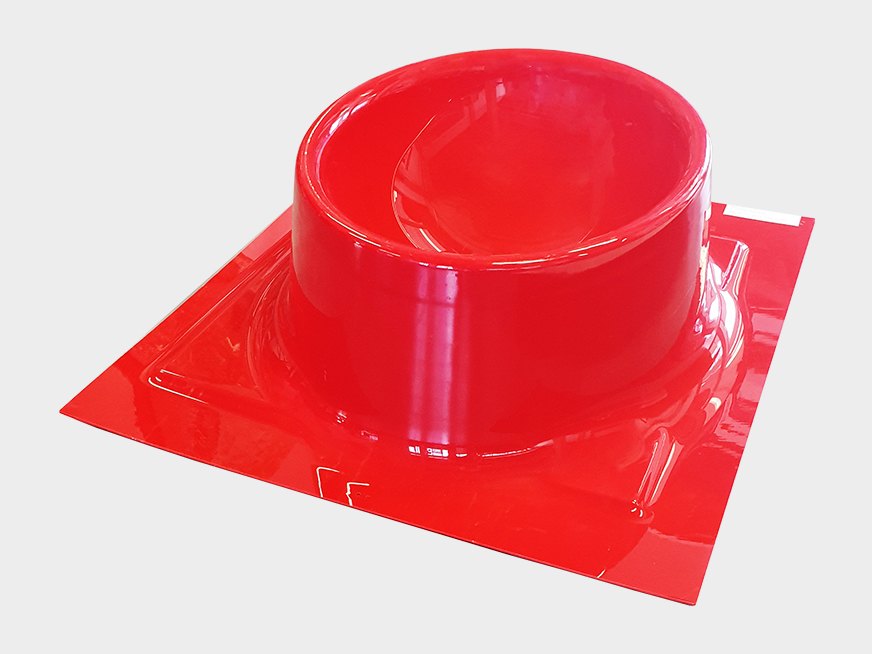

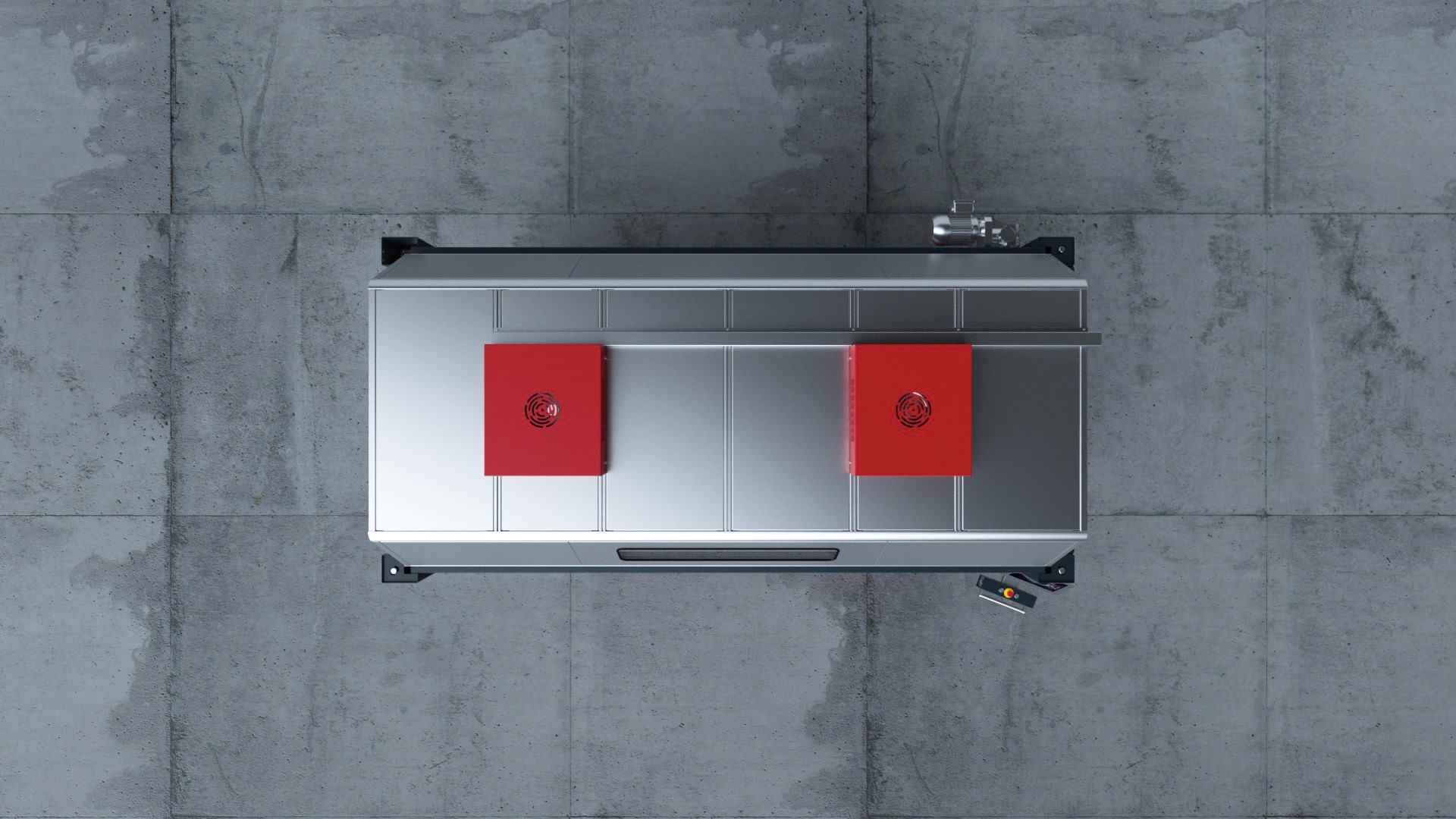

VACUUM TABLE

Precision vacuum table

Flap frame

Membrane frame

Natural rubber membrane

Silicone membrane economy

Silicone membrane high-performance

- Construction: stable steel construction with integrated vacuum storage system

- Feet: 4 pcs. table feet

- Wheels: 2 rigid castors & 2 swivel castors with parking brake

- Mountings for fork-lift: Removable front panel to reach fork-lift pick up points

- Color: gray blue RAL5008, powder-coated

- Overall dimensions: approx. 3320 x 1720 x 1000 mm (with flap frame)

- Working height: approx. 900 mm

Aluminium working surface

- Use: for thermoforming of plastic foils and sheets

- Size: 3200 x 1600 mm

- Material: aluminum AW5083 (CNC milled on both sides)

heat resistant up to + 250 ° C - Color: natural aluminum

- Vacuum channels: none

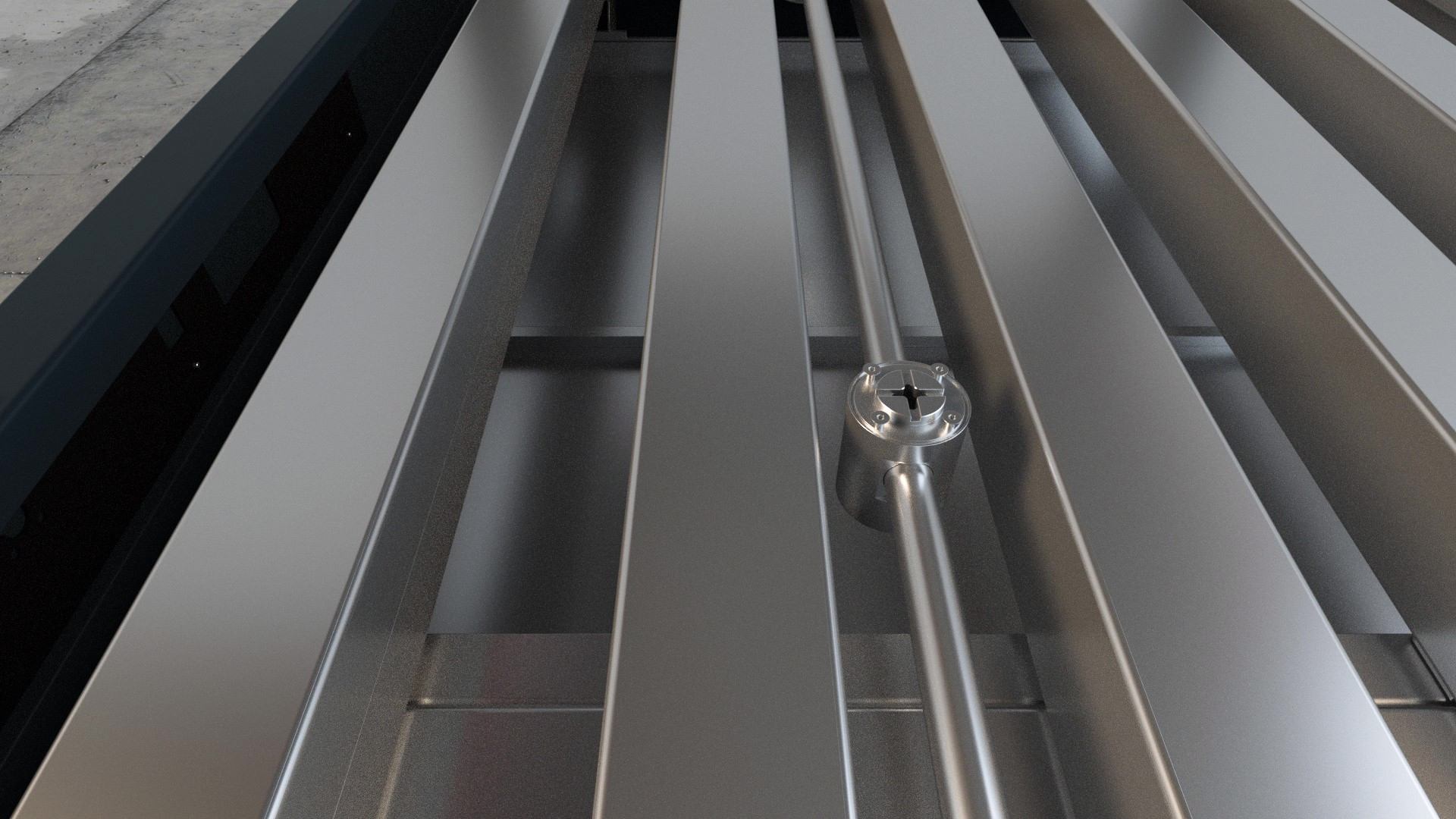

Vacuum technology

- Suction nozzles: 3 pcs. integrated in the working surface, CNC milled nozzles

- Connection system: hermetically sealed vacuum piping

- Vacuum storage system: 220 l integrated in the table

Operation: 3-way ball valve with manual control

Pump control: Pressure sensor for automatic control of the vacuum pump - Negative pressure display: pressure gauge

- Digital pressure regulator: optional for setting and automatic control of the desired negative pressure via digital display, built into the front panel

Flap frame

- Mounting fixture: fast-change system for membrane frames

- Pivot bearing: heavy load hinges (3-times beared)

- Swivel support: gas springs on both sides

- Locking: Locking clamp in solid steel design

- Color: blood orange RAL2002, powder-coated

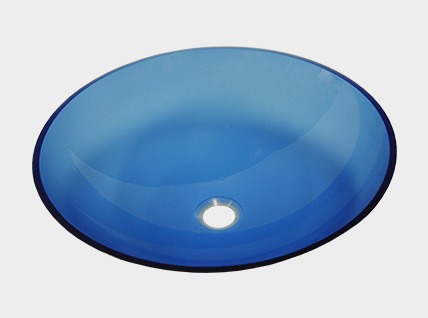

Membrane frame

- Dimensions inside the frame: approx. 3040 x 1440 mm

- Membrane holder: tool-free membrane fast-change system

- Assembly: fast-change system on the membrane frame

Natural rubber membrane

- Size: 3310 x 1710 x 2 mm

- Material: natural rubber NR

- Heat resistance: up to + 130 ° C

- Elongation at tear: 600%

- Material hardness: 40 Shore-A

- Color: gray

Silicone membrane economy

- Size: 3310 x 1710 x 2 mm

- Material: silicone

- Heat resistance: up to + 230 ° C

- Elongation at tear: 700% elongation

- Material hardness: 40 Shore-A

- Color: white / transparent

Silicone membrane high-performance

- Size: 3310 x 1710 x 2 mm

- Material: silicone

- Heat resistance: up to + 230 ° C

- Elongation at tear: 700% elongation

- Material hardness: 40 Shore-A

- Color: transparent

VACUUM PUMPS

40 m³ high-performance vacuum pump

80 m³ high-performance vacuum pump

only for VERTICAL with E + V-Tec large

- Type: rotary vane vacuum pump VT 4.40

- Air suction speed: 40 m³ / h

- Pressure: up to 9 t / m²

80 m³ high-performance vacuum pump

only for VERTICAL with E + V-Tec large

- Type: rotary vane vacuum pump VT 4.80

- Air suction speed: 80 m³ / h

- Pressure: up to 9 t / m²

VERTICAL OPENING SYSTEM

Vertical system

Universal frame carrier

Electromechanical precision drive

- Use: can be mounted on the basic construction of the vacuum table instead of the profile feet and the flap frame in order to be able to move the universal frame carrier vertically in a linear manner

- Construction: vertical corner columns (4 pcs.) with sturdy, stationary TR threaded spindles for mounting the universal frame carrier; with connecting struts; with maintenance doors

- Color: gray blue RAL5008, powder-coated

- Overall dimensions: approx. 3450 x 1750 x 2100 mm or approx. 3850 x 1750 x 2100 mm with electric cabinet

Universal frame carrier

- Construction: steel construction with corner bearings for vertical linear movement

- Preloading device: for the exact hermetic closure of the membrane frame to the working surface

- Pick-up device: fast-change system for membrane, foil or thermoforming frames

- Color: blood orange RAL2002, powder-coated

Electromechanical precision drive

- Drive: three-phase geared motor, moving along the universal frame carrier

- Engine power: 1.25 kW

- Lifting height: approx. 750 mm

- Operation: two-hand operation

- Travel speed: FU controlled up to approx. 50mm/s adjustable with soft start & stop

- Closing force: variably adjustable via control

- Parameter: adjustable via HMI touch panel

HEATING UNIT

Heating drawer

- Useable area: 2800 x 1300 x 70 mm

- Use: for heating of solid surface materials or plastics for subsequent forming

- Construction: at the bottom of the vacuum table

- Construction: steel construction with thermally separated, 2-shell structure with optimal thermal insulation with mineral wool in sheet metal cladding

- Drawer: heavy load drawer, located outside the heating chamber with soft touch close function and hyd. closing mechanism.

- Workpiece support: corrugated grid, galvanized with grid 30 x 30 mm

- Heating system: circulating air heating system with separate heating chamber

- Heating power: 2 x 10 kW high-performance heating coils

- Convection: 2 x radial fan 225 mm

- Temperature range: max. + 230 ° C

Temperature control: steplessly electronically adjustable via set point / actual value display

Temperature set point / actual value display via HMI touch panel

Exact pulse control via PLC with tuning function

Display of the heating process (widgets)

Monitoring function of the heating elements

Automatic shutdown

Programming and administration of recipes - Color: gray blue RAL5008, powder-coated

drawer front: blood orange RAL2002, powder-coated

HEATING HOOD

Heating hood

E+V-TEC LARGE

- Usable area: 3000 x 1140 x 500 mm

- Use: for heating foils and plastics for foiling or thermoforming

- Construction: mounted and vertically movable on the columns of the vertical system

- Construction: lightweight construction with thermally separated 2-shell construction with optimum thermal insulation with mineral wool Window with double pane

- Drive: three-phase geared motor, moving

- Engine power: 1.25 kW

- Lifting height: approx. 750 mm

- Operation: two-hand operation

- Travel speed: FU controlled up to approx. 50mm/s adjustable with soft start & stop

- Heating system: circulating air heating system with separate heating chamber

- Heating power: 2 x 10 kW high-performance heating coils

- Convection: 2 x radial fan 225 mm.

- Temperature range: max. + 210 ° C

- Control: Temperature set point / actual value display via HMI touch panel;

Exact pulse control via PLC with tuning function

Monitoring function of the heating elements. Automatic shutdown. Programming and administration of recipes - Color: hood; aluminium natural anodized

Substructure: Blood orange RAL2002, powder-coated - Requires: VERTICAL, E + V-Tec Large

E+V-TEC LARGE

- Use: PLC control and vacuum valves for the automated control and monitoring of all machine parts and functions. With touch display, where the HMI software for visualizing all processes is installed.

- PLC control: B & R Safety PLC

- HMI: touch panel with HMI software on ergonomically arranged operator console

- Vacuum pump: rotary vane vacuum pump VT 4.40 with 40m³/h air suction speed

- Evacuation valve: automatic 3-way ball valve, operation via HMI software

- Pressure build-up control: fully automatic vacuum valve for rapid evacuation with the vacuum storage system and for rapid pressure build-up

- Pressure monitoring: precise pressure sensors via PLC control

FRAMES

Foil frame

Deep drawing frame

- Use: for foiling fronts or other components

- Consists of: 1 pc. foil base frame with seal 1 pc. foil frame with fast-mounting system on the universal frame carrier; with silicone seal for clamping the foils

Deep drawing frame

- Use: for thermoforming of plastic foils and plates

- Consists of: 2 pcs. of grid rails, length-side with 50 grid 1 pc. deep drawing frame, B = 1250; length, selectable up to 1500mm other lengths on request, but max. 2800 mm

MISCELLANEOUS

Measuring sensor product

- Type: K-sensor with plug

- Cable length: 3 m

Perforated stainless steel sheet

- Size: 2000 x 1000 x 2 mm

- Perforation: 5 mm

Deionization unit

- Consists of: power supply with anti-static gun

- Air flow rate: adjustable Hose length: 6 m

Discover

new horizons

with us

Get prices

Get in touch with us and let us advise you in detail about the possibilities of our vacuum presses.

Thank you very much for your enquiry!

We will get back in touch with you.

We will get back in touch with you.