Move

The inexpensive and space-saving mobile vacuum press

Move

The inexpensive and space-saving mobile vacuum press

Move

The inexpensive and space-saving mobile vacuum press

Move

The inexpensive and space-saving

mobile vacuum press

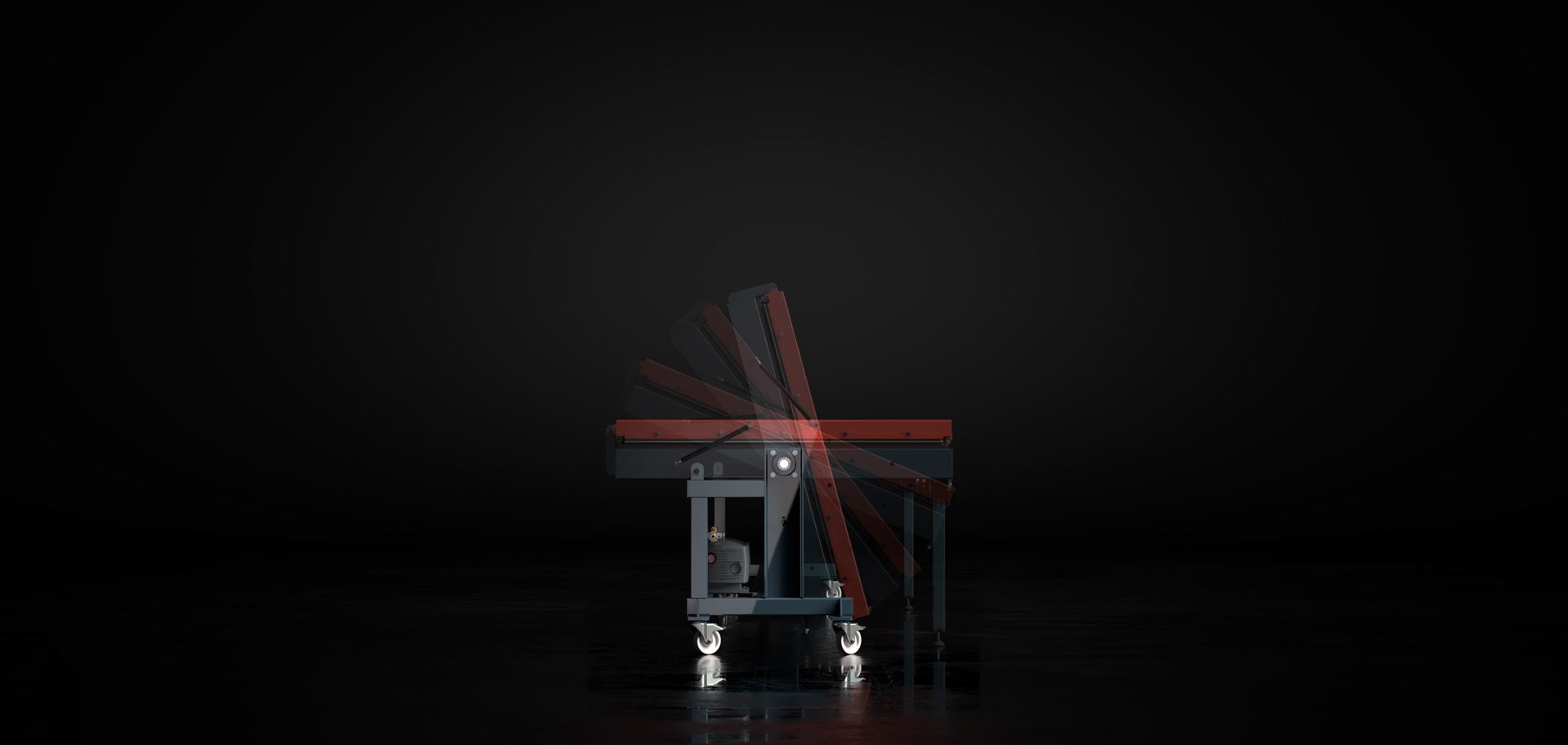

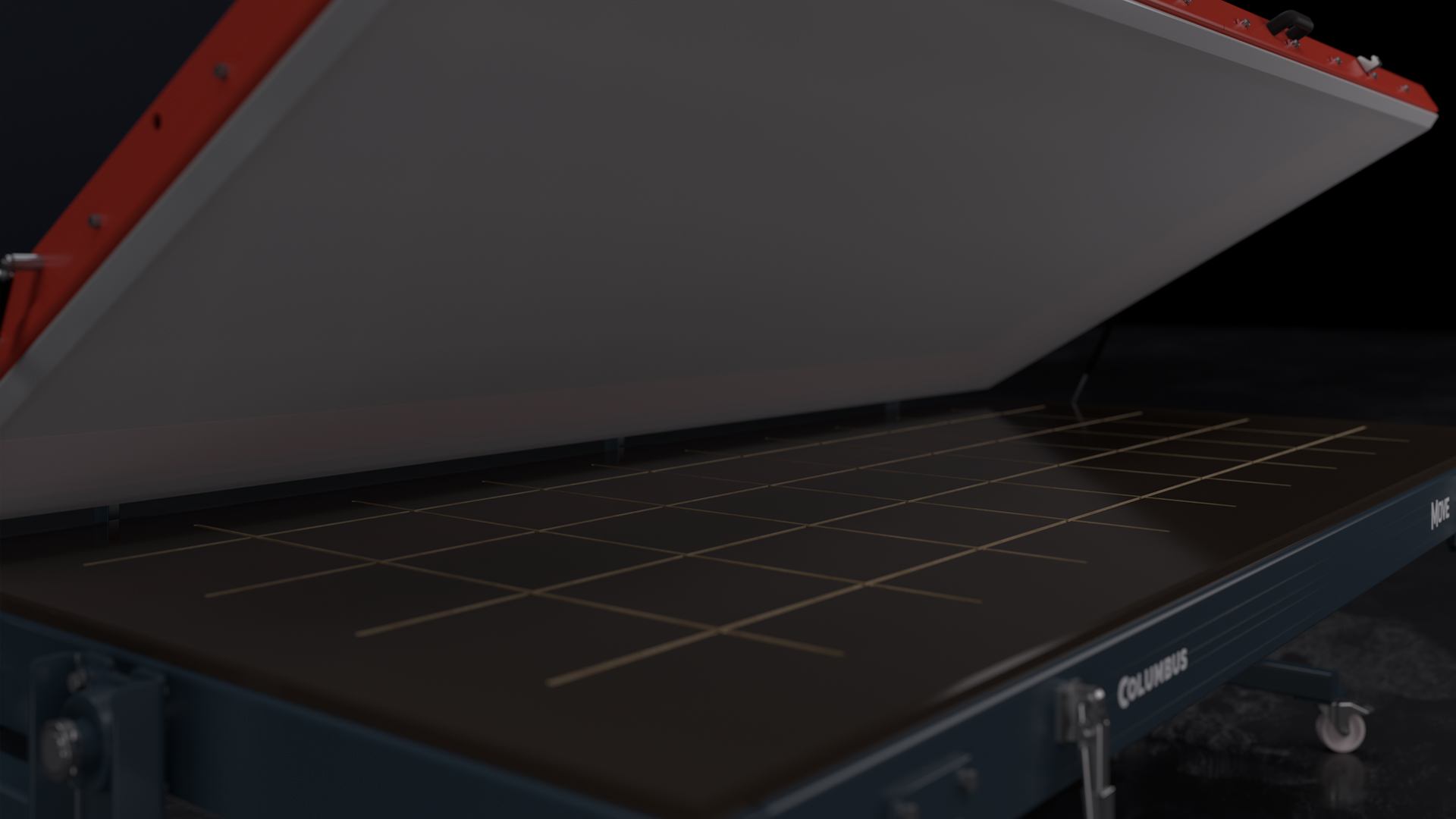

MOVE is the space-saving, mobile vacuum press for everyone who wants to benefit from the advantages of a full-fledged vacuum press for wood processing and at the same time wants to be particularly flexible. With MOVE, exceptional workpieces can be produced in no time through vacuum shape bonding and vacuum veneering. Thanks to the construction, designed for mobility, with 230 V power supply, castors and its foldable width, with which it fits through any standard door, MOVE is ready for use wherever it is needed. The integrated folding mechanism also enables MOVE to be stored in a space-saving manner (45% of the unfolded area) when it is not needed.

MOVE is mobile and also offers a gigantic usable area. In short — he is a flexible all-rounder with outstanding performance.

Experience the revolutionary

Folding mechanism of move!

The highlight of MOVE is the integrated folding mechanism. This allows the user to easily fold the vacuum table after use in a few simple steps. Through this process the floor space of MOVE can be reduced to 45 % of the unfolded area when it is not in use or has to be narrow enough to be transported through every room door. This flexibility makes MOVE the first choice for production companies who want to enjoy the advantages of their own vacuum press even when space is limited.

That is what Move can do

Depending on the configuration, MOVE allows you to perform the following applications. You will find many other useful information about the workflow, the possible fields of application as well as the compatible materials and material brands in the detailed information of the respective application.

Experience the variety

of possibilities

MOVE gives you the opportunity to perform multiple profitable applications. Due to this diversity, there are no limits to your own creativity and you can extend your product range and increase your sales with every new idea. The following impressions illustrate the incredible application variety of MOVE.

INTERESTING BLOG ARTICLE

Tailor-made perfection in Estonia

Haapsalu Uksetehase AS Manufactures Doors for Hampton by Hilton

Premium Interior Fittings and Yacht Furnishings

A Vacuum Press has supported Der Ernzerhof for many years

Flat veneering with vacuum

The use of a vacuum press as a veneer press

“It presses both flat and curved shapes”

Clairhout Interieur: A Revolution in Interior Design

Curving the Impossible with Columbus

Interwood sets new standards with the press

Precession and art from vacuum

Impressive eye model for the university clinic

Kempa from Belgium invests in 2 vacuum presses

Round & curved shapes for modern interior design

Columbus: Tips and Tricks from Practice

Mold making for mold bonding with vacuum

Skateboard ramps with the vacuum press Pioneer

Andreas Schützenberger does great things

1.5 weeks instead of 6 weeks production time

Precisely curved fronts of the DALI speakers

Handmade speakers from Denmark

One million satisfied DALI customers in over 70 countries

Columbus & University of Stuttgart

Artworks - Innovation meets Science

Sound loungers - feel the music

Magnus Hoffmann has developed something creative

Excellence as far as the eye can see

Acoustic panels for the Leonardian Center in Australia

Full speed ahead with a vacuum press

Tour buses for the biggest stars in the world

Columbus makes the impossible possible

VIDEO: Seamless veneering in just a few working steps

An Honor through Vacuum Technology

A chili as a creative lounge furniture is the winner

Hymer - a success story with vacuum

The well-known producer works with Columbus

The NDR works with a vacuum press

The Tagesschau desk was produced with Columbus

Key-Features

The unique

price-size ratio

price-size ratio

With a usable area of over 3 meters in length and almost 1.5 meters in width, MOVE offers more usable space as standard than comparable standard products on the market. Due to the robust and absolutely torsionally stable construction, you always get the highest precision during the pressing process. So MOVE guarantees absolutely uncompromising top results even after many hours of work. MOVE — quality from Austria at an unbeatable price.

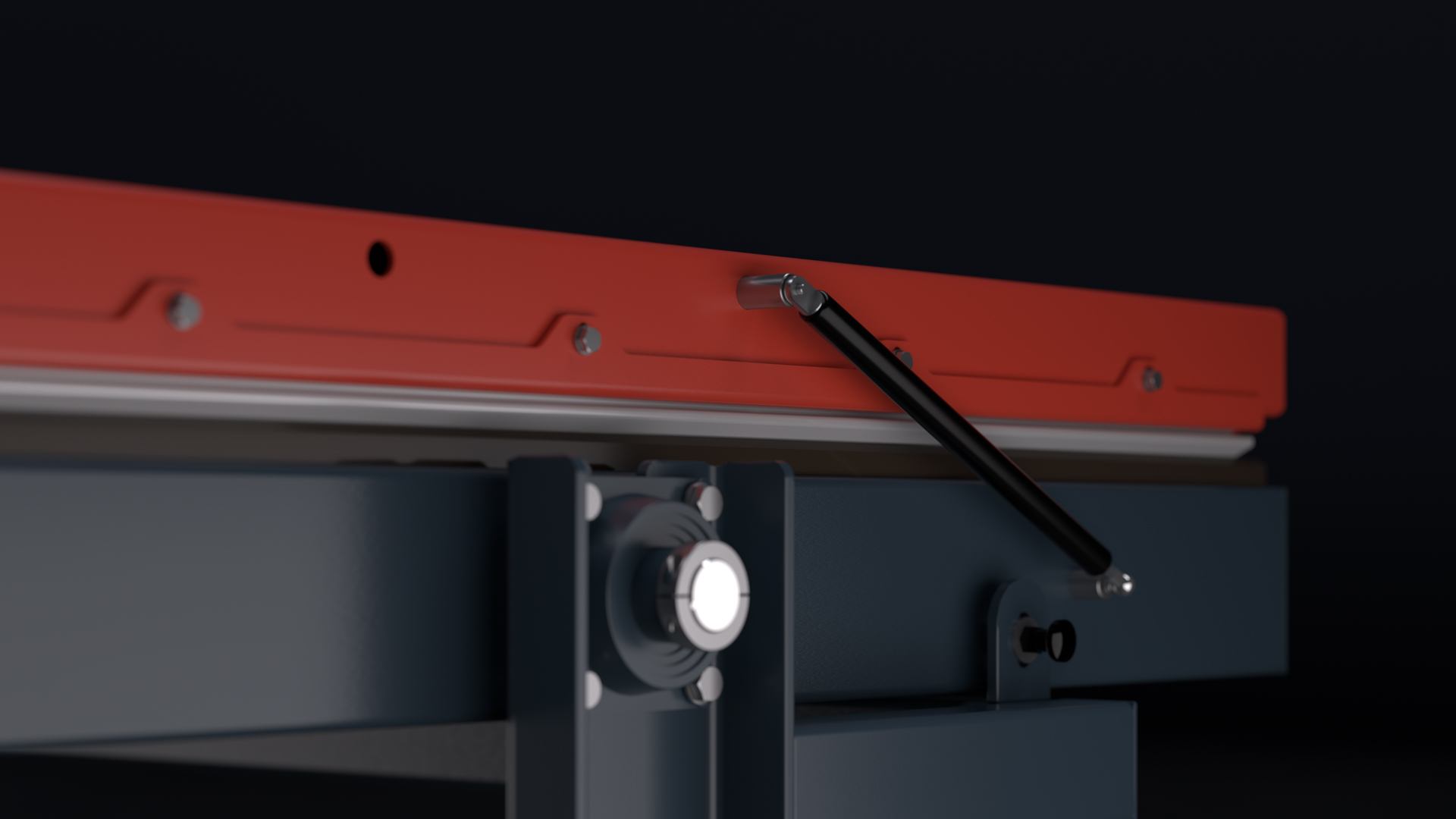

Key-Features

The revolutionary

folding mechanism

folding mechanism

The highlight of MOVE is the integrated folding mechanism. This allows the user to easily fold the vacuum table after use in a few simple steps. Through this process the floor space of MOVE can be reduced to 45 % of the unfolded area when it is not in use or has to be narrow enough to be transported through every room door. This flexibility makes MOVE the first choice for production companies who want to enjoy the advantages of their own vacuum press even when space is limited.

Key-Features

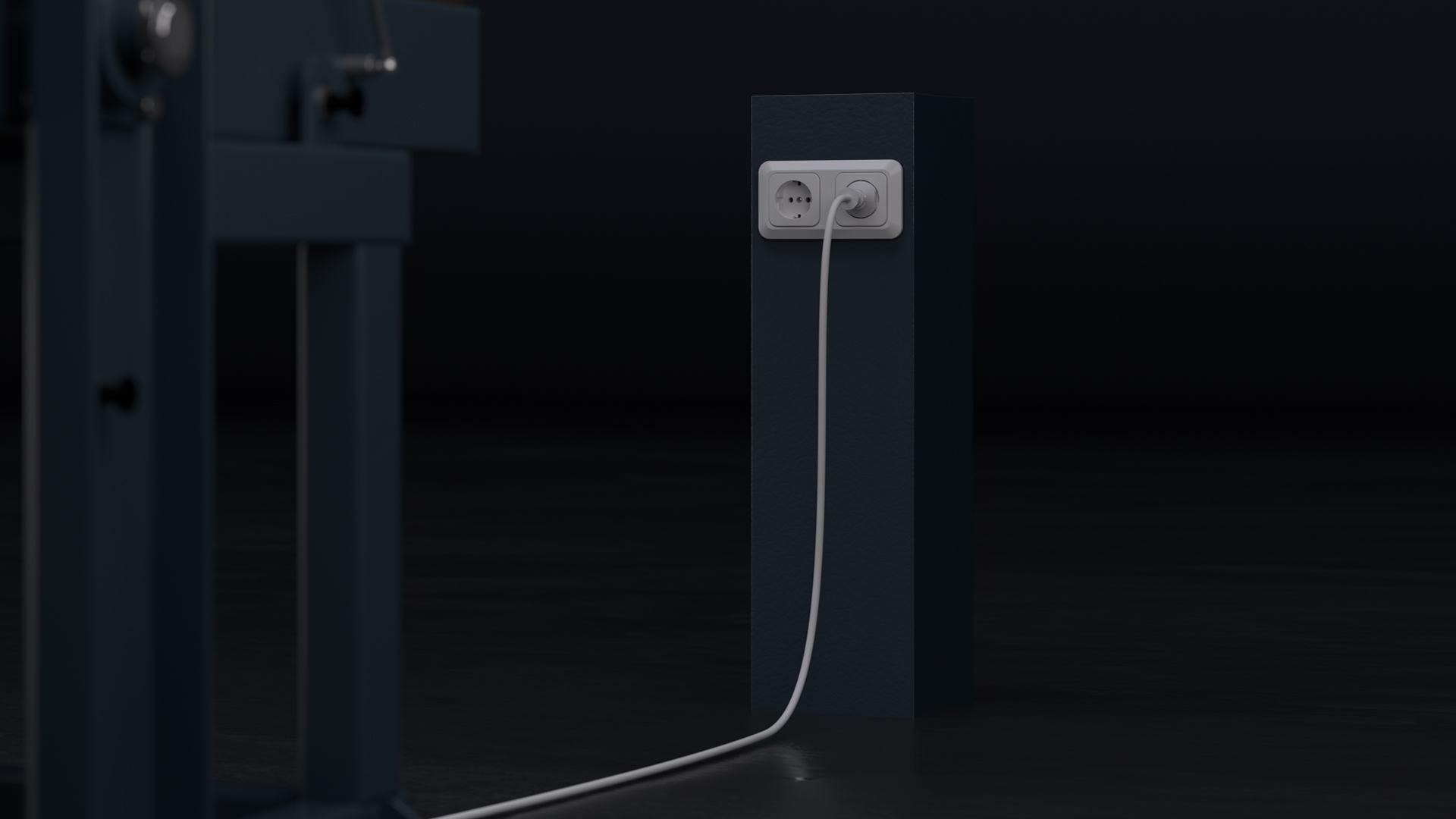

The 230 V

power supply

power supply

In order to take adequate account of the mobility and flexibility of MOVE, special attention was paid to the premise, that MOVE doesn’t require heavy current. It can be connected to any 230 volt socket. It can therefore be used almost anywhere. This guarantees that MOVE is not tied to a fixed location in any production company, but is where it is needed.

Key-Features

The membrane fast-

change system

change system

With the unique Columbus membrane quick-change system, a membrane change can be carried out in less than 10 minutes, which optimizes production processes, shortens production times and prevents longer downtimes. The stable frame guarantees a vacuum-tight membrane attachment and ensures the best press results and production reliability. The system is compatible with any Columbus natural rubber or silicone membrane.

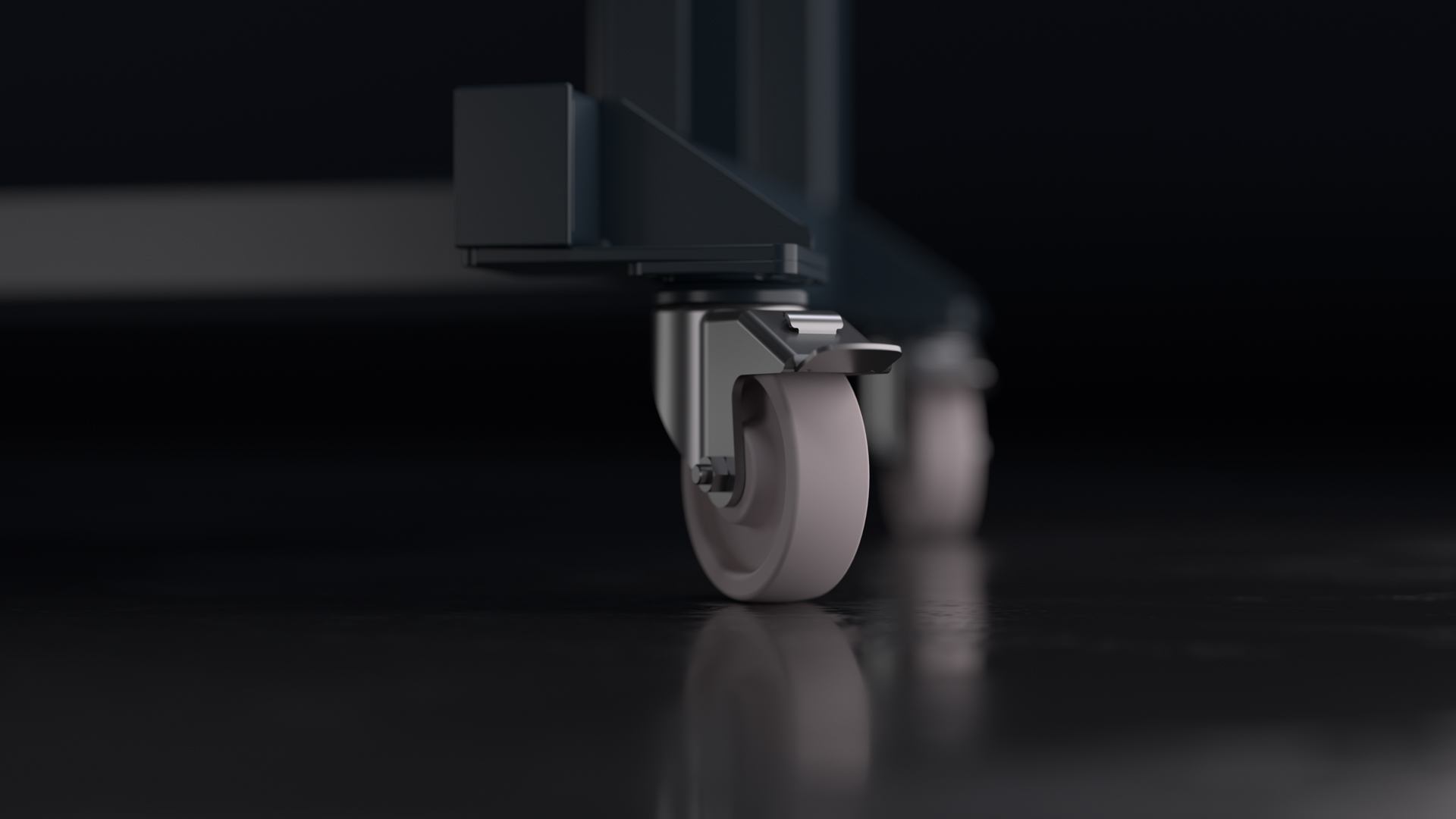

Key-Features

The smooth-running

swivel castors

swivel castors

Thanks to the smooth-running swivel castors, MOVE is quickly on site. The ergonomic operation makes the transporting and repositioning of the vacuum press particularly easy. This guarantees a body-friendly working method even when handled by a single person, which minimizes downtimes and ensures fatigue-free working.

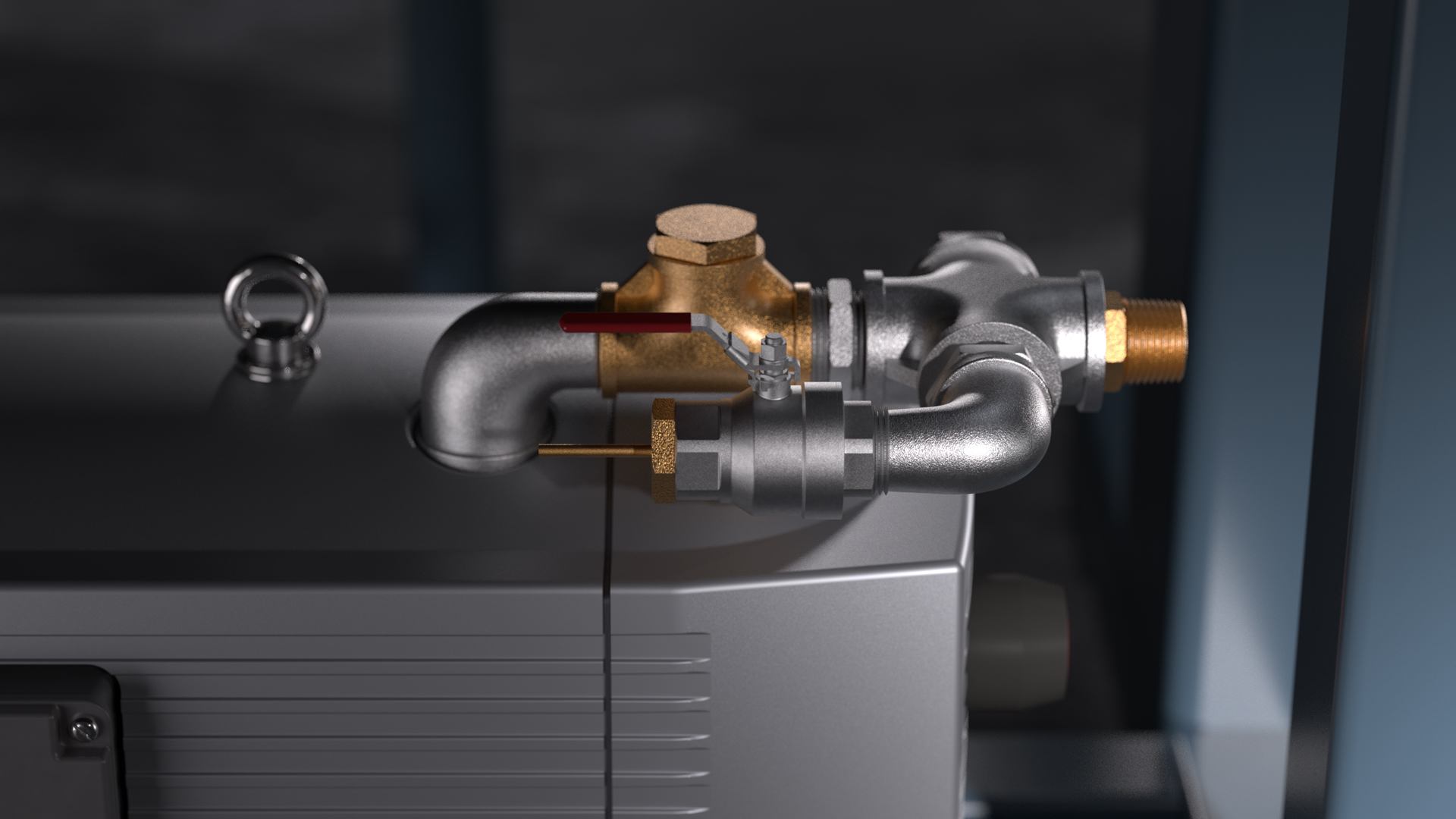

Key-Features

The standard 40m³

High-performance

vacuum pump

High-performance

vacuum pump

Columbus installs 40 m³ high-performance vacuum pumps as standard to guarantee users absolute flexibility and reliable results. The almost maintenance-free, dry-running rotary vane pumps with automatic switch-off are 100% oil-free, which ensures clean and safe production facilities for people, materials and the environment. Another advantage: With the use of this powerful pump, no vacuum boiler is necessary, which makes the system leaner, more effective and more resistant.

Key-Features

The integrated

vacuum bag

connection

vacuum bag

connection

With MOVE, users are not restricted to the size of the vacuum table with regard to the size of the workpieces to be machined. If a workpiece protrudes beyond the gigantic usable area of the vacuum press, an external vacuum bag can help. This is connected directly to the vacuum press and ensures feasibility for every project. Columbus vacuum bags are available in all desired dimensions.

Key-Features

The uncompromising

mobility principle

mobility principle

Many machines are already mobile these days. However, these are often bulky and therefore make it difficult to transport them from one location to the next. With MOVE, you don‘t need large production halls with car-wide doors between rooms. It was designed according to the premise, that it can be easily transported by one person to wherever it is needed. In this way it fits easily through every door when folded. This guarantees rapid operational readiness and the greatest possible flexibility.

contact form

Get prices

Get in touch with us and let us advise you in detail about the possibilities of our vacuum presses.

Thank you very much for your enquiry!

We will get back in touch with you.

We will get back in touch with you.

Close