With vacuum layer gluing and vacuum veneering to natural elegance

Once again, we received a success story from a satisfied Columbus customer who resolutely took the next step in his career as a carpenter with the help of vacuum technology. Today's story is about Lars Hackl - who created a piece of furniture that is perfected in its natural elegance.

The Columbus technology used – Vacuflex, the vacuum bag for professionals.

As part of the conception and production of his masterpiece, Lars had the task of implementing a family's special customer requirements. They live in an idyllic rural location, in a single-family house built in 2018, in which there is no uniform furnishing style. During the visit and determination of the wishes or requirements, the following key data were determined: furniture of high carpentry quality is available, types of wood are primarily oak and pine, panel furniture with white, smooth surfaces can also be seen, the walls are decorated with light gray patterned wallpaper, the floor has designer coverings in light gray and a violet carpet.

According to the description, the customers are looking for a decorative, functional furniture that creates the symbiosis of modern, clear edges and natural curves of nature. In addition, the shape of a treetop should flow into the design. Functionally, the piece of furniture should offer storage space on the one hand, and on the other hand it should be possible to write or sign on the surface. A light source should also be available for this purpose, which can also serve as a secondary accent lighting.

The key data mentioned required an early search for a form for the piece of furniture.

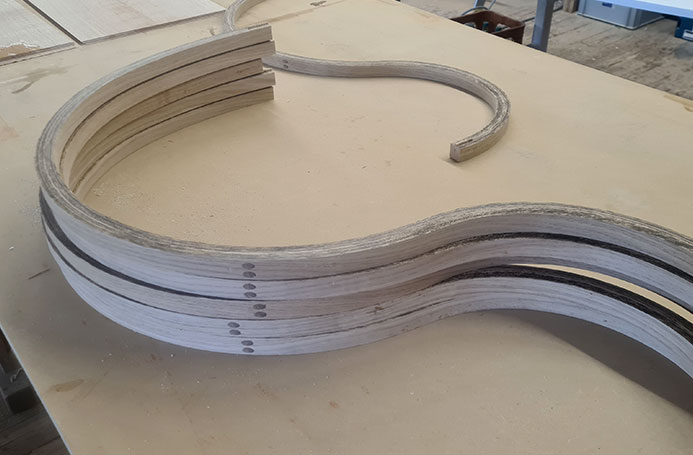

The use of a frame construction, which rises above the body and thus offers as much volume as possible with a relatively small space requirement, is both meaningful and appropriate. The frame is divided into individual small slats, similar to the branches of a crown. The slats were manufactured by gluing them into shape using the Vacuflex vacuum bag. A visual highlight, of course, they get their strength from solid brass bases and bolts running vertically from the front to the back. The angular stability of the piece of furniture is guaranteed with four oppositely curved slats below the body. The left and right side of the slats is connected below the body via frames. The body rests on these frames. The rear left slat rises far above the other slats and the body and offers the perfect space for a slotted LED rail. The lamp is operated conveniently via an IR sensor directly on the lamp. The remaining slats on the left make a small kink and thus provide a storage area for documents.

The body clearly distinguishes itself and brings calmness to the design. It speaks a very straightforward design language, without many offsets and without curves. The body consists of veneered laminboard with Hdf deck. The veneer was also attached using the Vacuflex vacuum bag. The front is essentially divided into three well-proportioned fields. These fields are formed by a sliding door on the left and right and two drawers of the same size in the middle field. The sliding doors run in a groove milled into the body and are held in place with magnets on the side of the body. The drawers are guided mechanically in order to always guarantee perfect function. The sliding doors and drawers are fitted with a brass handle shell.

The drawers now offer the perfect storage space for writing utensils, and the compartments behind the drawers provide plenty of storage space for games or documents. Behind the right rear wall there is an offset in the interior of the body, which is covered by an internal rear wall. This is where the transformer for the Led light is housed. The cable guide is grooved in the rear slat and is reversibly sealed with cork.

When choosing the wood, the European oak came into play for the frame and thus for the form gluing. Perfectly processed with the Vacuflex vacuum bag. Since there was a desire for another unusual wood, the body itself was made in Jatoba, from tropical Central and South America. This wood offers a beautiful purple accent on its own. Since this type of wood is quite rare, it also fulfills this special customer request. The choice is also well made in terms of design, because the color matches numerous decorative accents of the customer. The fittings and a writing tablet embedded in the lid were made of brass, which has a certain inherent warmth. The brass components, such as the shell handle, writing surface, connectors on the slats, sliding door guides, base feet and the rods between the slats were manufactured with polished brass surfaces. The surface of the ChannelLine C - the lamp - was finished with a brass-colored metal paint. The use of a third color pushes the maximum, but does not exceed it. The effect of the furniture remains calm and elegant. With this construction and design of the Modern Drop, all customer requests are implemented in the best possible way.

We are excited. This is exactly what the vacuum bag was developed for, back then by Columbus founder Günther Vetter. In order to be able to fulfill special customer requests and to make them possible and to minimize the effort effectively. You can find out first-hand how the vacuum bag was invented in a video here.

We wish Lars Hackl all the best and thank him for sharing his story.

You want to know more about Lars Hackl:

Website: www.holzstolz-gmbh.de

Instagram: holzstolz_gmbh

The Columbus technology used – Vacuflex, the vacuum bag for professionals.

Visit and starting point

As part of the conception and production of his masterpiece, Lars had the task of implementing a family's special customer requirements. They live in an idyllic rural location, in a single-family house built in 2018, in which there is no uniform furnishing style. During the visit and determination of the wishes or requirements, the following key data were determined: furniture of high carpentry quality is available, types of wood are primarily oak and pine, panel furniture with white, smooth surfaces can also be seen, the walls are decorated with light gray patterned wallpaper, the floor has designer coverings in light gray and a violet carpet.

The customer request

According to the description, the customers are looking for a decorative, functional furniture that creates the symbiosis of modern, clear edges and natural curves of nature. In addition, the shape of a treetop should flow into the design. Functionally, the piece of furniture should offer storage space on the one hand, and on the other hand it should be possible to write or sign on the surface. A light source should also be available for this purpose, which can also serve as a secondary accent lighting.

Structure and composition

The key data mentioned required an early search for a form for the piece of furniture.

The frame construction – a curved layer glued workpiece, similar to a crown.

The use of a frame construction, which rises above the body and thus offers as much volume as possible with a relatively small space requirement, is both meaningful and appropriate. The frame is divided into individual small slats, similar to the branches of a crown. The slats were manufactured by gluing them into shape using the Vacuflex vacuum bag. A visual highlight, of course, they get their strength from solid brass bases and bolts running vertically from the front to the back. The angular stability of the piece of furniture is guaranteed with four oppositely curved slats below the body. The left and right side of the slats is connected below the body via frames. The body rests on these frames. The rear left slat rises far above the other slats and the body and offers the perfect space for a slotted LED rail. The lamp is operated conveniently via an IR sensor directly on the lamp. The remaining slats on the left make a small kink and thus provide a storage area for documents.

The body – linear design, well-proportioned.

The body clearly distinguishes itself and brings calmness to the design. It speaks a very straightforward design language, without many offsets and without curves. The body consists of veneered laminboard with Hdf deck. The veneer was also attached using the Vacuflex vacuum bag. The front is essentially divided into three well-proportioned fields. These fields are formed by a sliding door on the left and right and two drawers of the same size in the middle field. The sliding doors run in a groove milled into the body and are held in place with magnets on the side of the body. The drawers are guided mechanically in order to always guarantee perfect function. The sliding doors and drawers are fitted with a brass handle shell.

The drawers now offer the perfect storage space for writing utensils, and the compartments behind the drawers provide plenty of storage space for games or documents. Behind the right rear wall there is an offset in the interior of the body, which is covered by an internal rear wall. This is where the transformer for the Led light is housed. The cable guide is grooved in the rear slat and is reversibly sealed with cork.

The choice of materials

When choosing the wood, the European oak came into play for the frame and thus for the form gluing. Perfectly processed with the Vacuflex vacuum bag. Since there was a desire for another unusual wood, the body itself was made in Jatoba, from tropical Central and South America. This wood offers a beautiful purple accent on its own. Since this type of wood is quite rare, it also fulfills this special customer request. The choice is also well made in terms of design, because the color matches numerous decorative accents of the customer. The fittings and a writing tablet embedded in the lid were made of brass, which has a certain inherent warmth. The brass components, such as the shell handle, writing surface, connectors on the slats, sliding door guides, base feet and the rods between the slats were manufactured with polished brass surfaces. The surface of the ChannelLine C - the lamp - was finished with a brass-colored metal paint. The use of a third color pushes the maximum, but does not exceed it. The effect of the furniture remains calm and elegant. With this construction and design of the Modern Drop, all customer requests are implemented in the best possible way.

Conclusion

We are excited. This is exactly what the vacuum bag was developed for, back then by Columbus founder Günther Vetter. In order to be able to fulfill special customer requests and to make them possible and to minimize the effort effectively. You can find out first-hand how the vacuum bag was invented in a video here.

We wish Lars Hackl all the best and thank him for sharing his story.

You want to know more about Lars Hackl:

Website: www.holzstolz-gmbh.de

Instagram: holzstolz_gmbh

Interest?

IMPORTANT : Nous répondons rapidement à toutes les demandes. Si vous ne recevez pas de réponse de notre part, veuillez vérifier votre dossier de courriers indésirables ou nous contacter !

We would be happy to inform you about the vacuum bag, your options, all versions, prices, etc.

Merci pour votre demande!

Nous vous contacterons dans les plus brefs délais.

Nous vous contacterons dans les plus brefs délais.

ARTICLES DE BLOG INTÉRESSANTS

De l'arrondi au classement

comment utiliser stratégiquement la tendance en design d'intérieur

Why I Developed Columbus 360°

50 Years of Columbus – and a System That Changes Everything

Réaliser des visions

La précision suisse rencontre le design créatif

La perfection sur mesure en Estonie

Haapsalu Uksetehase AS fabrique des portes pour Hampton by Hilton

Conception et aménagement intérieur haut de gamme pour yachts

Une presse à vide soutient l'Ernzerhof depuis de nombreuses années.

Agencement de magasin exceptionnel avec technologie du vide

"außerdem" exploite les avantages d'une presse à vide Columbus

Placage des surfaces planes

L'utilisation d'une presse à vide comme presse à placage

Un savoir-faire exceptionnel

La garde-robe pour l'examen de maître menuisier

«Elle presse aussi bien les formes plates que courbes.»

Clairhout Interiors : une révolution dans le design d'intérieur

Un client de Columbus crée un chef-d'œuvre artistique

Publicité pour Jean Paul Gaultier à Santiago du Chili

Idée cadeau intéressante

My Esel – vélos et vélos électriques extraordinaires

Dépasser les limites du possible

Interwood établit de nouvelles normes de conception avec la presse à vide Columbus.

Infinity pour camping-cars bimobil

Perfection à grande échelle pour peinture haute brillance

Precession and art from vacuum

Modèle d'œil impressionnant pour l'hôpital universitaire

De la corbeille à fruits à la structure du plafond

Les possibilités d'application d'une presse à vide

L'outil de changement de pression Columbus

Pour empêcher le caoutchouc naturel de déformer l'acier

Kempa, une entreprise belge, investit dans 2 presses à vide.

Formes rondes et courbes pour un design d'intérieur moderne

Un brevet pour le système modulaire

Tout le monde disait que ça ne marcherait pas - j'y croyais, moi.

Columbus : Conseils et astuces pratiques

Fabrication de moules pour le collage sous vide

Un aperçu des coulisses de Columbus

Merci papa, pour ce merveilleux voyage à tes côtés.

Un aperçu des coulisses de Columbus

Günther Vetter – l’invention du sac sous vide

Rampes de skateboard avec Pioneer

Andreas Schützenberger accomplit de grandes choses à l'échelle mondiale

Protégez vos employés et votre entreprise

Formation obligatoire sur les adhésifs thermofusibles PUR

Sac sous vide : ZOSIA de Robert Nößler

Son chef-d'œuvre, empreint de nostalgie et d'un secret

Quels sont les avantages d'une presse à vide ?

Ce ne sont pas seulement les pièces courbes qui le prouvent

Rapport : Salon international du commerce en mai 2023

Grand succès au salon LIGNA à Hanovre

Cap sur de nouveaux horizons, avec le chef-d'œuvre de Tommy Kairat

Placage de première qualité avec le sac sous vide Vacuflex

matériaux minéraux

Libérez tout le potentiel d'une presse à vide

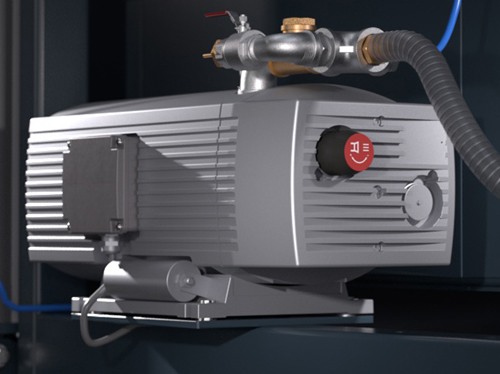

Pompes à vide

Columbus démontre les avantages des machines fonctionnant à sec

La créativité libre dans le processus créatif

Élèves de l'école Waldorf libre de Mayence

Délai de production de 1,5 semaine au lieu de 6 semaines.

Façades incurvées précises des haut-parleurs DALI

Sac sous vide : Chef-d'œuvre de Markus Kramer

Le passé français dans le présent

C'était le Holz-Handwerk 2022

Succès spectaculaire pour PIONEER et MOVE lors des salons professionnels.

La magie réside dans les détails parfaits.

LL Installations crée des éléments décoratifs de haute qualité.

Haut-parleurs artisanaux du Danemark

Un million de clients DALI satisfaits dans plus de 70 pays

Columbus et l'Université de Stuttgart

Œuvres d'art - L'innovation rencontre la science

Indépendance vis-à-vis des entreprises fournisseurs

6 raisons d'acheter une presse à vide

La naissance de l'Infinity

Flexstone fabrique des pièces de grande taille pour les péniches.

Des fonds sonores de Pure Works - ressentez la musique

Magnus Hoffmann a créé quelque chose de créatif.

L'excellence à perte de vue

Panneaux acoustiques pour le Centre Léonardien / Australie

Une collaboration éblouissante entre deux pionniers

Vide - Verre acrylique - des possibilités infinies

MAINTENANT - Individuel. Unique. Exceptionnel.

Meilleures performances en technologie du vide à partir d'un lot de taille 1

Un composé meilleur que le bois

Resysta : Le design au service du développement durable

Sac sous vide : White River de Jannik Otte

Un chef-d'œuvre qui attire le regard dans l'espace d'entrée.

La créativité des jeunes conquiert le monde

Ce sont des étudiants, pas des charpentiers.

En avant toute avec une presse à vide

Des bus de tournée pour les plus grandes stars du monde

Première mondiale : Chaise en verre acrylique

Le client Zöllner fabrique pour Acrylic Couture

Columbus rend l'impossible possible

VIDÉO : Placage sans joint en quelques étapes seulement

Columbus déforme Kerrock en Belgique

Un avenir extraordinaire en matière de design

Le fabricant de stands d'exposition Prager produit pour Siemens

Un stand d'exposition innovant utilisant la technologie du vide

Les temps nouveaux apportent de nouvelles opportunités

Conquérir les marchés existants grâce à de nouvelles applications

C'était Holz 2019 à Bâle.

Columbus et les grands charpentiers suisses

Coopération avec Schachmayer

Columbus s'offre un autre partenaire de poids.

Presse : On parle de Columbus.

Ce qui est publié à notre sujet dans les milieux professionnels

POINT DE RENCONTRE : Initiative EDELFURNIER

Visite de l'entreprise Schachermayer à Linz

Un prix grâce à la technologie du vide

Un piment transformé en meuble lounge original, c'est gagnant !

Hymer – Une réussite dans le domaine des aspirateurs

Le célèbre producteur travaille avec Columbus.

Le NDR utilise une presse à vide

Le bureau Tagesschau a été produit en collaboration avec Columbus.

Pourquoi nous appelons-nous comme nous l'appelons?

Quel est le lien entre Christophe Colomb et Columbus?