Spectacular success at the trade fair with the live presentation of the vacuum presses PIONEER and MOVE.

Already on the first day it was clear – this Holz-Handwerk will be different. A special energy of optimism, of hands-on mentality and of the cohesion of the craft community was noticeable, and this lasted until the very last visitor had left the exhibition center. It was a great reunion of many colleagues, who are connected at heart by a single cause, and genuine interested parties who are passionate about one thing. It wasn't just a trade fair, it was – in the truest sense of the word – a celebration, celebrating an entire industry.

Craftsmanship is real, craftsmanship is living and craftsmanship must be seen, felt and touched. Of course, we are all the happier to finally be able to meet our customers personally again after this long break. Because it is only possible in a personal conversation to fully understand what is important to our fellow craftsmen and how we can support them in the best possible way, says Ruth Koppenberger, CEO of Columbus.

Of course, the market launch of PIONEER could not be stopped by the pandemic, but unfortunately had to take place virtually in 2020. At this year's Holz-Handwerk, the live presentation has finally been rescheduled and celebrated a great success. It was as if the anticipation had only increased over time.

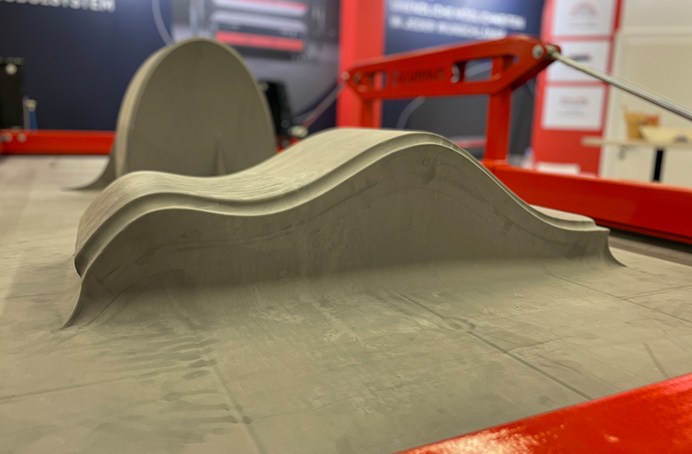

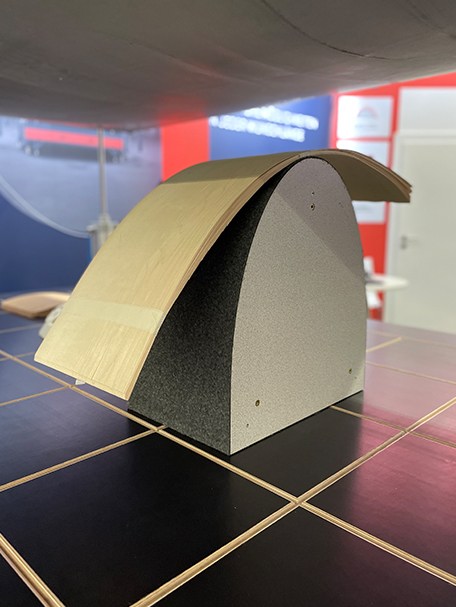

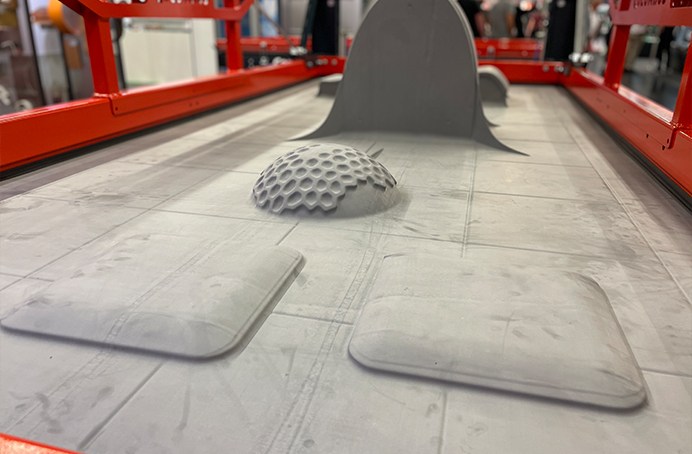

PIONEER is the first patented vacuum press modular system. The high-quality vacuum press is available in 3 different sizes and, based on PIONEER BASIC – the high-precision vacuum table with flap opening – can be upgraded with 2 individual modules. On the one hand with the module called VERTICAL – the vertical opening system – for processing very high workpieces. On the other hand with the module called HEAT – the external high-performance heating system – for heating up plastics for subsequent forming on the vacuum table.

In this way, PIONEER offers the possibility of producing extraordinary workpieces by laminated bending, form-veneering and forming solid surface materials and plastics.

In addition to PIONEER, two other new machines from Columbus were presented.

MOVE – the inexpensive and space-saving mobile vacuum press was exhibited live directly at the booth. MOVE offers all the advantages of a vacuum press for wood processing but is particularly flexible. Thanks to the construction designed for mobility with 230 V connection, castors and the revolutionary folding mechanism (only 45 % space requirement) with which it fits through any standard door, MOVE is ready for use wherever it is needed.

INFINITY – the vacuum press system in special lengths - could not be exhibited live due to its size, but was welcomed with particular interest. We invite all interested parties who are looking for a vacuum press of 10 meters length or more at an excellent price to find out more HERE.

A personal highlight for the Columbus team, which was represented at the trade fair, was the opportunity to meet many well-known and friendly dealers again. The warm words about the good cooperation over the years were particularly pleasing. We are happy and really appreciate working with such a great dealer network, where appreciation and honesty are lived with every cell. Because that is also the Columbus philosophy.

Columbus finally breathed trade fair air again and what else can we say than: It feels great. Now it goes on. For this reason, Columbus decided to also present the new machines at the LIGNA in Hanover. So, save the date: May 15 - 19, 2023. We’ll be there!

In summary, it can be said that the Holz-Handwerk was a wonderful start to a new era. We were able to collect many impressions and wishes from our customers and interested parties and are fully motivated to catapult the wood and plastic processing companies further towards success.

Craftsmanship is real, craftsmanship is living and craftsmanship must be seen, felt and touched. Of course, we are all the happier to finally be able to meet our customers personally again after this long break. Because it is only possible in a personal conversation to fully understand what is important to our fellow craftsmen and how we can support them in the best possible way, says Ruth Koppenberger, CEO of Columbus.

First live presentation of the patented vacuum press modular system PIONEER

Of course, the market launch of PIONEER could not be stopped by the pandemic, but unfortunately had to take place virtually in 2020. At this year's Holz-Handwerk, the live presentation has finally been rescheduled and celebrated a great success. It was as if the anticipation had only increased over time.

PIONEER is the first patented vacuum press modular system. The high-quality vacuum press is available in 3 different sizes and, based on PIONEER BASIC – the high-precision vacuum table with flap opening – can be upgraded with 2 individual modules. On the one hand with the module called VERTICAL – the vertical opening system – for processing very high workpieces. On the other hand with the module called HEAT – the external high-performance heating system – for heating up plastics for subsequent forming on the vacuum table.

In this way, PIONEER offers the possibility of producing extraordinary workpieces by laminated bending, form-veneering and forming solid surface materials and plastics.

MOVE and INFINITY – the new stars with very special abilities

In addition to PIONEER, two other new machines from Columbus were presented.

MOVE – the inexpensive and space-saving mobile vacuum press was exhibited live directly at the booth. MOVE offers all the advantages of a vacuum press for wood processing but is particularly flexible. Thanks to the construction designed for mobility with 230 V connection, castors and the revolutionary folding mechanism (only 45 % space requirement) with which it fits through any standard door, MOVE is ready for use wherever it is needed.

INFINITY – the vacuum press system in special lengths - could not be exhibited live due to its size, but was welcomed with particular interest. We invite all interested parties who are looking for a vacuum press of 10 meters length or more at an excellent price to find out more HERE.

A great reunion with Columbus dealers

A personal highlight for the Columbus team, which was represented at the trade fair, was the opportunity to meet many well-known and friendly dealers again. The warm words about the good cooperation over the years were particularly pleasing. We are happy and really appreciate working with such a great dealer network, where appreciation and honesty are lived with every cell. Because that is also the Columbus philosophy.

Next step – LIGNA Hanover

Columbus finally breathed trade fair air again and what else can we say than: It feels great. Now it goes on. For this reason, Columbus decided to also present the new machines at the LIGNA in Hanover. So, save the date: May 15 - 19, 2023. We’ll be there!

In summary, it can be said that the Holz-Handwerk was a wonderful start to a new era. We were able to collect many impressions and wishes from our customers and interested parties and are fully motivated to catapult the wood and plastic processing companies further towards success.

Interest?

IMPORTANT : Nous répondons rapidement à toutes les demandes. Si vous ne recevez pas de réponse de notre part, veuillez vérifier votre dossier de courriers indésirables ou nous contacter !

If you would like to know more about vacuum technologie, we would be happy to provide you with more information!

Merci pour votre demande!

Nous vous contacterons dans les plus brefs délais.

Nous vous contacterons dans les plus brefs délais.

ARTICLES DE BLOG INTÉRESSANTS

De l'arrondi au classement

comment utiliser stratégiquement la tendance en design d'intérieur

Why I Developed Columbus 360°

50 Years of Columbus – and a System That Changes Everything

Réaliser des visions

La précision suisse rencontre le design créatif

La perfection sur mesure en Estonie

Haapsalu Uksetehase AS fabrique des portes pour Hampton by Hilton

Conception et aménagement intérieur haut de gamme pour yachts

Une presse à vide soutient l'Ernzerhof depuis de nombreuses années.

Agencement de magasin exceptionnel avec technologie du vide

"außerdem" exploite les avantages d'une presse à vide Columbus

Placage des surfaces planes

L'utilisation d'une presse à vide comme presse à placage

Un savoir-faire exceptionnel

La garde-robe pour l'examen de maître menuisier

«Elle presse aussi bien les formes plates que courbes.»

Clairhout Interiors : une révolution dans le design d'intérieur

Un client de Columbus crée un chef-d'œuvre artistique

Publicité pour Jean Paul Gaultier à Santiago du Chili

Idée cadeau intéressante

My Esel – vélos et vélos électriques extraordinaires

Dépasser les limites du possible

Interwood établit de nouvelles normes de conception avec la presse à vide Columbus.

Infinity pour camping-cars bimobil

Perfection à grande échelle pour peinture haute brillance

Precession and art from vacuum

Modèle d'œil impressionnant pour l'hôpital universitaire

De la corbeille à fruits à la structure du plafond

Les possibilités d'application d'une presse à vide

L'outil de changement de pression Columbus

Pour empêcher le caoutchouc naturel de déformer l'acier

Kempa, une entreprise belge, investit dans 2 presses à vide.

Formes rondes et courbes pour un design d'intérieur moderne

Un brevet pour le système modulaire

Tout le monde disait que ça ne marcherait pas - j'y croyais, moi.

Columbus : Conseils et astuces pratiques

Fabrication de moules pour le collage sous vide

Un aperçu des coulisses de Columbus

Merci papa, pour ce merveilleux voyage à tes côtés.

Un aperçu des coulisses de Columbus

Günther Vetter – l’invention du sac sous vide

Rampes de skateboard avec Pioneer

Andreas Schützenberger accomplit de grandes choses à l'échelle mondiale

Protégez vos employés et votre entreprise

Formation obligatoire sur les adhésifs thermofusibles PUR

Sac sous vide : ZOSIA de Robert Nößler

Son chef-d'œuvre, empreint de nostalgie et d'un secret

Quels sont les avantages d'une presse à vide ?

Ce ne sont pas seulement les pièces courbes qui le prouvent

Rapport : Salon international du commerce en mai 2023

Grand succès au salon LIGNA à Hanovre

Sac sous vide : Modern Drop par Lars Hackl

Collage par couches pour le chef-d'œuvre

Cap sur de nouveaux horizons, avec le chef-d'œuvre de Tommy Kairat

Placage de première qualité avec le sac sous vide Vacuflex

matériaux minéraux

Libérez tout le potentiel d'une presse à vide

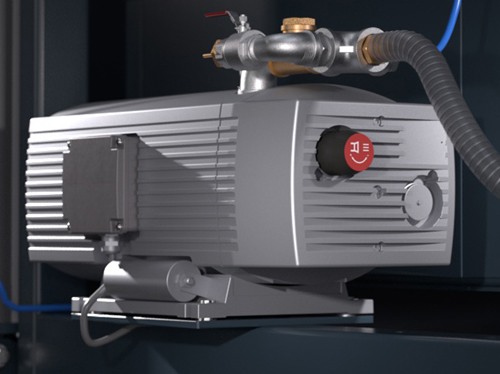

Pompes à vide

Columbus démontre les avantages des machines fonctionnant à sec

La créativité libre dans le processus créatif

Élèves de l'école Waldorf libre de Mayence

Délai de production de 1,5 semaine au lieu de 6 semaines.

Façades incurvées précises des haut-parleurs DALI

Sac sous vide : Chef-d'œuvre de Markus Kramer

Le passé français dans le présent

La magie réside dans les détails parfaits.

LL Installations crée des éléments décoratifs de haute qualité.

Haut-parleurs artisanaux du Danemark

Un million de clients DALI satisfaits dans plus de 70 pays

Columbus et l'Université de Stuttgart

Œuvres d'art - L'innovation rencontre la science

Indépendance vis-à-vis des entreprises fournisseurs

6 raisons d'acheter une presse à vide

La naissance de l'Infinity

Flexstone fabrique des pièces de grande taille pour les péniches.

Des fonds sonores de Pure Works - ressentez la musique

Magnus Hoffmann a créé quelque chose de créatif.

L'excellence à perte de vue

Panneaux acoustiques pour le Centre Léonardien / Australie

Une collaboration éblouissante entre deux pionniers

Vide - Verre acrylique - des possibilités infinies

MAINTENANT - Individuel. Unique. Exceptionnel.

Meilleures performances en technologie du vide à partir d'un lot de taille 1

Un composé meilleur que le bois

Resysta : Le design au service du développement durable

Sac sous vide : White River de Jannik Otte

Un chef-d'œuvre qui attire le regard dans l'espace d'entrée.

La créativité des jeunes conquiert le monde

Ce sont des étudiants, pas des charpentiers.

En avant toute avec une presse à vide

Des bus de tournée pour les plus grandes stars du monde

Première mondiale : Chaise en verre acrylique

Le client Zöllner fabrique pour Acrylic Couture

Columbus rend l'impossible possible

VIDÉO : Placage sans joint en quelques étapes seulement

Columbus déforme Kerrock en Belgique

Un avenir extraordinaire en matière de design

Le fabricant de stands d'exposition Prager produit pour Siemens

Un stand d'exposition innovant utilisant la technologie du vide

Les temps nouveaux apportent de nouvelles opportunités

Conquérir les marchés existants grâce à de nouvelles applications

C'était Holz 2019 à Bâle.

Columbus et les grands charpentiers suisses

Coopération avec Schachmayer

Columbus s'offre un autre partenaire de poids.

Presse : On parle de Columbus.

Ce qui est publié à notre sujet dans les milieux professionnels

POINT DE RENCONTRE : Initiative EDELFURNIER

Visite de l'entreprise Schachermayer à Linz

Un prix grâce à la technologie du vide

Un piment transformé en meuble lounge original, c'est gagnant !

Hymer – Une réussite dans le domaine des aspirateurs

Le célèbre producteur travaille avec Columbus.

Le NDR utilise une presse à vide

Le bureau Tagesschau a été produit en collaboration avec Columbus.

Pourquoi nous appelons-nous comme nous l'appelons?

Quel est le lien entre Christophe Colomb et Columbus?