With vacuum layer gluing and vacuum veneering to natural elegance

Once again, we received a success story from a satisfied Columbus customer who resolutely took the next step in his career as a carpenter with the help of vacuum technology. Today's story is about Lars Hackl - who created a piece of furniture that is perfected in its natural elegance.

The Columbus technology used – Vacuflex, the vacuum bag for professionals.

As part of the conception and production of his masterpiece, Lars had the task of implementing a family's special customer requirements. They live in an idyllic rural location, in a single-family house built in 2018, in which there is no uniform furnishing style. During the visit and determination of the wishes or requirements, the following key data were determined: furniture of high carpentry quality is available, types of wood are primarily oak and pine, panel furniture with white, smooth surfaces can also be seen, the walls are decorated with light gray patterned wallpaper, the floor has designer coverings in light gray and a violet carpet.

According to the description, the customers are looking for a decorative, functional furniture that creates the symbiosis of modern, clear edges and natural curves of nature. In addition, the shape of a treetop should flow into the design. Functionally, the piece of furniture should offer storage space on the one hand, and on the other hand it should be possible to write or sign on the surface. A light source should also be available for this purpose, which can also serve as a secondary accent lighting.

The key data mentioned required an early search for a form for the piece of furniture.

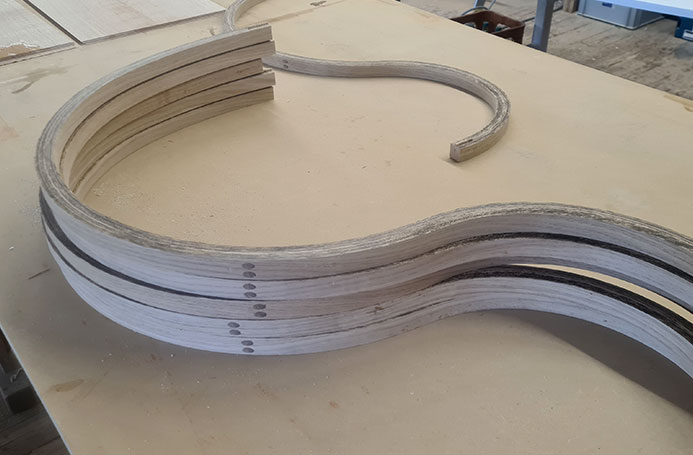

The use of a frame construction, which rises above the body and thus offers as much volume as possible with a relatively small space requirement, is both meaningful and appropriate. The frame is divided into individual small slats, similar to the branches of a crown. The slats were manufactured by gluing them into shape using the Vacuflex vacuum bag. A visual highlight, of course, they get their strength from solid brass bases and bolts running vertically from the front to the back. The angular stability of the piece of furniture is guaranteed with four oppositely curved slats below the body. The left and right side of the slats is connected below the body via frames. The body rests on these frames. The rear left slat rises far above the other slats and the body and offers the perfect space for a slotted LED rail. The lamp is operated conveniently via an IR sensor directly on the lamp. The remaining slats on the left make a small kink and thus provide a storage area for documents.

The body clearly distinguishes itself and brings calmness to the design. It speaks a very straightforward design language, without many offsets and without curves. The body consists of veneered laminboard with Hdf deck. The veneer was also attached using the Vacuflex vacuum bag. The front is essentially divided into three well-proportioned fields. These fields are formed by a sliding door on the left and right and two drawers of the same size in the middle field. The sliding doors run in a groove milled into the body and are held in place with magnets on the side of the body. The drawers are guided mechanically in order to always guarantee perfect function. The sliding doors and drawers are fitted with a brass handle shell.

The drawers now offer the perfect storage space for writing utensils, and the compartments behind the drawers provide plenty of storage space for games or documents. Behind the right rear wall there is an offset in the interior of the body, which is covered by an internal rear wall. This is where the transformer for the Led light is housed. The cable guide is grooved in the rear slat and is reversibly sealed with cork.

When choosing the wood, the European oak came into play for the frame and thus for the form gluing. Perfectly processed with the Vacuflex vacuum bag. Since there was a desire for another unusual wood, the body itself was made in Jatoba, from tropical Central and South America. This wood offers a beautiful purple accent on its own. Since this type of wood is quite rare, it also fulfills this special customer request. The choice is also well made in terms of design, because the color matches numerous decorative accents of the customer. The fittings and a writing tablet embedded in the lid were made of brass, which has a certain inherent warmth. The brass components, such as the shell handle, writing surface, connectors on the slats, sliding door guides, base feet and the rods between the slats were manufactured with polished brass surfaces. The surface of the ChannelLine C - the lamp - was finished with a brass-colored metal paint. The use of a third color pushes the maximum, but does not exceed it. The effect of the furniture remains calm and elegant. With this construction and design of the Modern Drop, all customer requests are implemented in the best possible way.

We are excited. This is exactly what the vacuum bag was developed for, back then by Columbus founder Günther Vetter. In order to be able to fulfill special customer requests and to make them possible and to minimize the effort effectively. You can find out first-hand how the vacuum bag was invented in a video here.

We wish Lars Hackl all the best and thank him for sharing his story.

You want to know more about Lars Hackl:

Website: www.holzstolz-gmbh.de

Instagram: holzstolz_gmbh

The Columbus technology used – Vacuflex, the vacuum bag for professionals.

Visit and starting point

As part of the conception and production of his masterpiece, Lars had the task of implementing a family's special customer requirements. They live in an idyllic rural location, in a single-family house built in 2018, in which there is no uniform furnishing style. During the visit and determination of the wishes or requirements, the following key data were determined: furniture of high carpentry quality is available, types of wood are primarily oak and pine, panel furniture with white, smooth surfaces can also be seen, the walls are decorated with light gray patterned wallpaper, the floor has designer coverings in light gray and a violet carpet.

The customer request

According to the description, the customers are looking for a decorative, functional furniture that creates the symbiosis of modern, clear edges and natural curves of nature. In addition, the shape of a treetop should flow into the design. Functionally, the piece of furniture should offer storage space on the one hand, and on the other hand it should be possible to write or sign on the surface. A light source should also be available for this purpose, which can also serve as a secondary accent lighting.

Structure and composition

The key data mentioned required an early search for a form for the piece of furniture.

The frame construction – a curved layer glued workpiece, similar to a crown.

The use of a frame construction, which rises above the body and thus offers as much volume as possible with a relatively small space requirement, is both meaningful and appropriate. The frame is divided into individual small slats, similar to the branches of a crown. The slats were manufactured by gluing them into shape using the Vacuflex vacuum bag. A visual highlight, of course, they get their strength from solid brass bases and bolts running vertically from the front to the back. The angular stability of the piece of furniture is guaranteed with four oppositely curved slats below the body. The left and right side of the slats is connected below the body via frames. The body rests on these frames. The rear left slat rises far above the other slats and the body and offers the perfect space for a slotted LED rail. The lamp is operated conveniently via an IR sensor directly on the lamp. The remaining slats on the left make a small kink and thus provide a storage area for documents.

The body – linear design, well-proportioned.

The body clearly distinguishes itself and brings calmness to the design. It speaks a very straightforward design language, without many offsets and without curves. The body consists of veneered laminboard with Hdf deck. The veneer was also attached using the Vacuflex vacuum bag. The front is essentially divided into three well-proportioned fields. These fields are formed by a sliding door on the left and right and two drawers of the same size in the middle field. The sliding doors run in a groove milled into the body and are held in place with magnets on the side of the body. The drawers are guided mechanically in order to always guarantee perfect function. The sliding doors and drawers are fitted with a brass handle shell.

The drawers now offer the perfect storage space for writing utensils, and the compartments behind the drawers provide plenty of storage space for games or documents. Behind the right rear wall there is an offset in the interior of the body, which is covered by an internal rear wall. This is where the transformer for the Led light is housed. The cable guide is grooved in the rear slat and is reversibly sealed with cork.

The choice of materials

When choosing the wood, the European oak came into play for the frame and thus for the form gluing. Perfectly processed with the Vacuflex vacuum bag. Since there was a desire for another unusual wood, the body itself was made in Jatoba, from tropical Central and South America. This wood offers a beautiful purple accent on its own. Since this type of wood is quite rare, it also fulfills this special customer request. The choice is also well made in terms of design, because the color matches numerous decorative accents of the customer. The fittings and a writing tablet embedded in the lid were made of brass, which has a certain inherent warmth. The brass components, such as the shell handle, writing surface, connectors on the slats, sliding door guides, base feet and the rods between the slats were manufactured with polished brass surfaces. The surface of the ChannelLine C - the lamp - was finished with a brass-colored metal paint. The use of a third color pushes the maximum, but does not exceed it. The effect of the furniture remains calm and elegant. With this construction and design of the Modern Drop, all customer requests are implemented in the best possible way.

Conclusion

We are excited. This is exactly what the vacuum bag was developed for, back then by Columbus founder Günther Vetter. In order to be able to fulfill special customer requests and to make them possible and to minimize the effort effectively. You can find out first-hand how the vacuum bag was invented in a video here.

We wish Lars Hackl all the best and thank him for sharing his story.

You want to know more about Lars Hackl:

Website: www.holzstolz-gmbh.de

Instagram: holzstolz_gmbh

Interest?

IMPORTANT: We respond to every inquiry promptly. If you don't hear from us, please check your spam folder or contact us!

We would be happy to inform you about the vacuum bag, your options, all versions, prices, etc.

Thank you very much for your inquiry!

We will get back in touch with you.

INTERESTING BLOG ARTICLE

Why I Developed Columbus 360°

50 Years of Columbus – and a System That Changes Everything

Realising Visions

Swiss Precision Meets Creative Design

Tailor-made perfection in Estonia

Haapsalu Uksetehase AS Manufactures Doors for Hampton by Hilton

Premium Interior Fittings and Yacht Furnishings

A Vacuum Press has supported Der Ernzerhof for many years

Outstanding Shopfitting with Vacuum

"außerdem" utilizes the advantages of a vacuum press by Columbus

Flat veneering with vacuum

The use of a vacuum press as a veneer press

Masterful craftsmanship

The Wardrobe for the Master Carpenter Exam

“It presses both flat and curved shapes”

Clairhout Interieur: A Revolution in Interior Design

Columbus customer creates artistic masterpiece

Advertisement for Jean Paul Gaultier in Santiago de Chile

Beautiful Gift Idea

My Esel – exceptional bicycles & e-bikes

Curving the Impossible

Interwood Pushes Design Boundaries with the Columbus Vacuum Press

Infinity for bimobil motorhomes

Large-scale perfection, because high-gloss paint is unforgiving

Precession and art from vacuum

Ziegler creates impressive eye model for the university clinic

From Very Small to Very Large

The Diversity of Applications of a Vacuum Press

The Columbus Pressure Shifting Tool

Natural rubber bends steel

Kempa from Belgium invests in 2 vacuum presses

Round and curved shapes are particularly popular in interior design

the patented modular system

Everyone said it doesn't work - I believed in it

Mold making for mold gluing with vacuum

Practical tips and tricks

Thank you, dad

for the big things, but also for so many small ones

The invention of the Vacuum Bag

Interview with Günther Vetter about the origin of vacuum technology

Skateboard ramps with the vacuum press Pioneer

Andreas Schützenberger does great things around the world

Protect your employees and your company

training for PUR hot melt adhesives

ZOSIA by Robert Nößler

His masterpiece with nostalgia and a hidden secret

Why a vacuum press?

You can use it not only to cover curved workpieces...

Fair in May 2023

LIGNA in Hanover

Off to new shores with Tommy Kairat's masterpiece

First-class form veneering with the Vacuflex Vacuum Bag

Solid surface materials

Unleash the full potential with a vacuum press

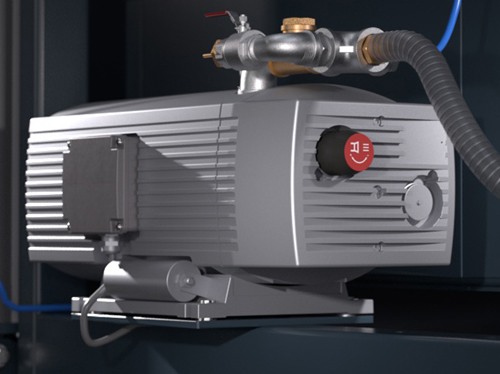

Vacuum pumps

Columbus shows the advantages of dry runners

Free creativity in the creating process

Students from the Freie Waldorfschule Mainz create truly unique items using vacuum technology

1.5 weeks instead of 6 weeks production time

Curved fronts on DALI speakers made in a vacuum press

Markus Kramer's masterpiece

His vision brings the French past into the present

That was the Holz-Handwerk 2022

Spectacular success at the trade fair with the live presentation of PIONEER and MOVE.

The magic is in the details

LL Installations creates high-quality accents in a foyer with Corian

Handmade speakers from Denmark

Customer DALI delights over a million customers in over 70 countries with handcrafted loudspeakers.

Columbus & University of Stuttgart

Innovation meets science!

More success through independence from suppliers

6 reasons for a vacuum press

Beyond all dimensions

Flexstone manufactures large boat parts with INFINITY

Feel the musice

Magnus Hoffmann has developed something particularly creative

Excellence as far as the eye can see

Acoustic panels for the Leonardian Center in Australia

A dazzling cooperation between two pioneers

Vacuum technology. Acrylic glass. Unlimited possibilities.

Individual. Exceptional. Unique.

Best performance with batch size 1

Resysta - A compound better than wood

Design meets sustainability

White River by Jannik Otte

Masterpiece as an eye-catcher for the entrance area

Young creativity

Students - not carpenters!

Full speed ahead with Vacuplus

The tour buses of the world's greatest stars

World premiere: acrylic glass chair

Customer Zöllner manufactures for Acrylic Couture

Columbus makes the impossible possible

VIDEO: Seamless veneering in just a few working steps

Columbus forms Kerrock in Belgium

An exceptional design future

Prager manufactures for Siemens

An innovative trade fair booth

New times bring new opportunities.

How to conquer existing markets by using new applications and materials.

That was the Holz 2019

Columbus and the great Swiss carpenters

Cooperation with Schachermayer

Columbus receives another strong partner

People talk about Columbus

What is published in professional circles about us

MEETING POINT NOBLE VENEER

Visiting the Schachermayer company

Success through vacuum technology

A chili produced with vacuum

Customer Story

Hymer

Customer Story

North German Broadcasting works with Columbus

Columbus Story

Why Columbus?