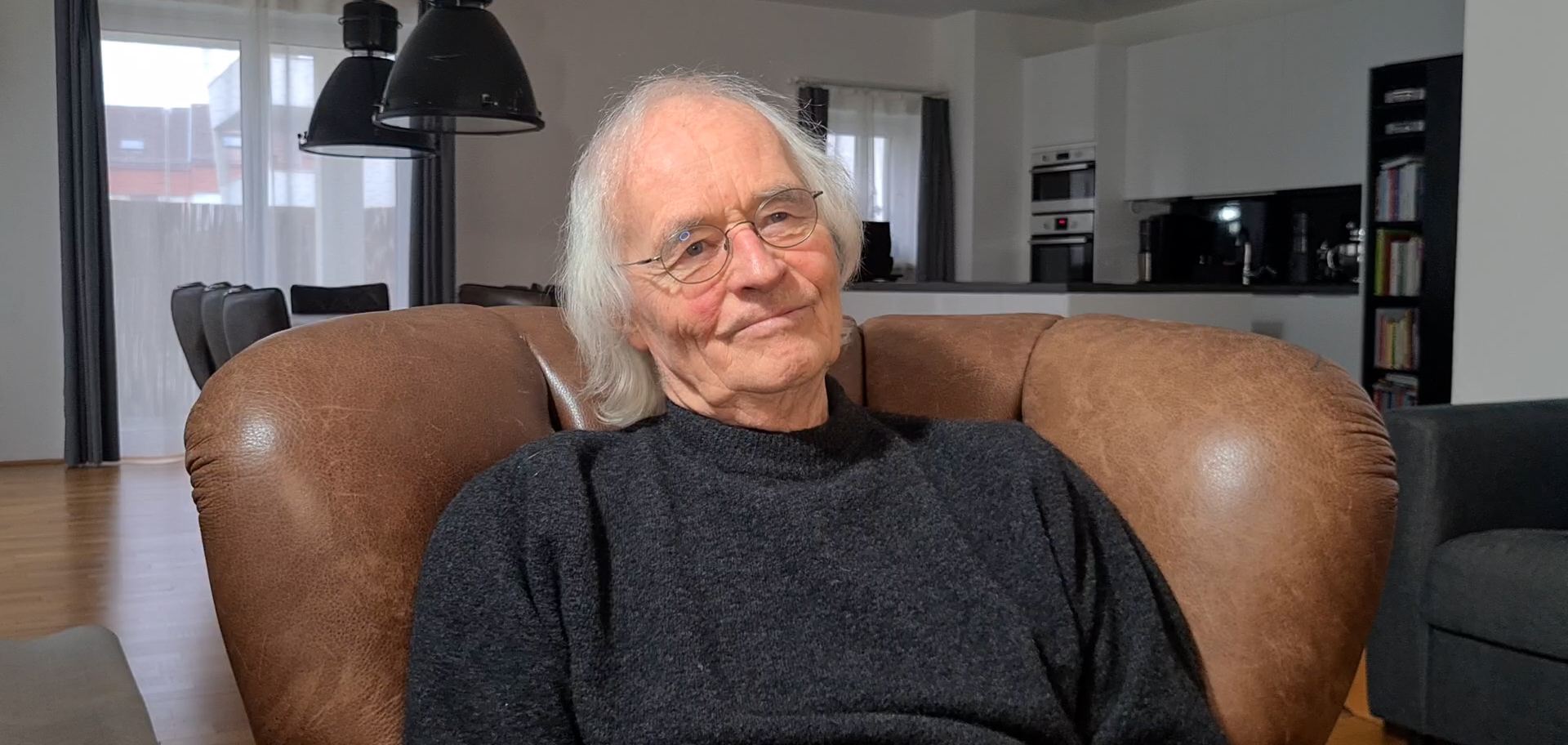

The interview with Günther Vetter about the origin of vacuum technology

Das Video kann leider nicht abgespielt werden!

Sie können das Video aber über folgenden Link herunterladen:

Sie können das Video aber über folgenden Link herunterladen:

Download Video

THE Interview:

THE Invention of the Vacuum Bag

Ruth Koppenberger:

Hello. It is wonderful that you're here. I am

very pleased that you want to share the story with us and I would like to ask

you to wallow in memories and tell us how it all started back then. With the

ancestors, with my ancestors, with our ancestors.

I remember that grandpa, your father, had the

carpentry shop in Kirchdorf. And your grandfather, your mother's father, had a

carpentry shop in Pressburg – even a relatively large one, as far as I know -

before the war.

Günther Vetter:

Yes, that's right. And what I sometimes

noticed from my parents was that they had a very well run carpentry shop. My

grandfather ran the carpentry shop and my father was empolyed there. My father

was a master carpenter and my mother worked there in accounting and in

calculation. And the two met and got married. And then three children arised

from that marriage, three children were born.

And then the war came and my parents had to

flee and leave everything behind. The entire facilities, the carpentry, the

apartment and everything. And so they fled for a long time sometimes by foot

and often only with their hand luggage, because they couldn't take more with

them, via Linz to Kirchdorf and built a new life there. They bought a property and

built a little house, a single family home with a carpentry shop in the

basement and on the first floor, I mean in the ground floor.

And there I learned carpentry. I was born in

Austria and did my apprenticeship as a carpenter as well as the journeyman's

examination at my father’s carpentry shop, and then I went to Hallstatt to the

master school and there I did a lot of technical drawings, architecture and interior

design and so on, in addition to carpentry training and passed the master

craftsman's examination.

And then I came back I took over the carpentry

business from my father and I had already transformed many of my creative

visions into a reality back then. My ideas and my creativity were of course not

paid extra.

That was the selling point, so to speak, why

they came to me and, for example, had me design the interior of their bedroom or

design the interior of their coffee shop. That's how I developed a certain name

for myself, of course. And then people came to me with special requests. And

this design work has expanded more and more, so that I have given up carpentry and

literally have only been a designer. Anyways, and over time this design work

has moved more and more towards invention. New ideas have always been very

important to me. Not just designing the surface, but also redeveloping the

function.

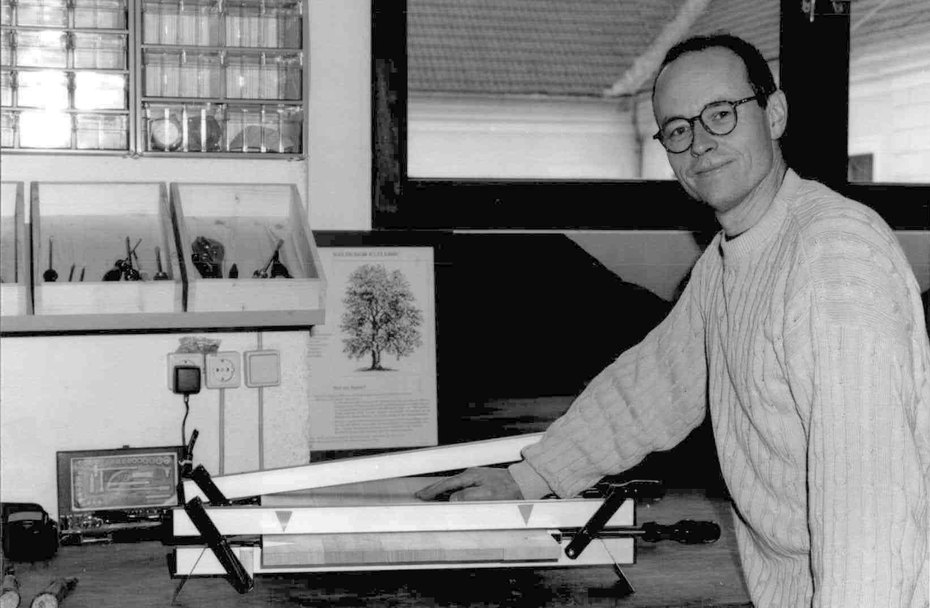

And then it went more and more in the

direction of of carpentry facilities and auxiliary equipment. Yes, sometimes

machines as well. And that's how the new company developed, the company

Columbus, and this company then sold these inventions, which were very often

patented, and the patents as well.

And above all – because I was out there a lot

with the carpenters – I kept getting ideas from the carpenters, about problems which

I then tried to solve with new inventions.

And that's how the vacuum bag was invented. There

was always a problem when producing curved parts an covering them and so on. That

was very complex with a template and counter template.

And with the vacuum bag there was no need for

a counter template an one could produce and cover these curved parts without

much effort. And from that came the Vacuflex, a vacuum press, which was no

longer a bag, but had a work surface with a folding frame.

In that folding frame an elastic cloth was

clamped and so of course the operation was much more comfortable and much more

accurate. One could place the respective product on the work surface and close

the folding frame and then press what needs to be pressed with a vacuum. Then

of course the next step came, the warming up, the heating. Partly from above, to

reduce the pressing time, or we have constructed our own heating drawer, for

under the machine, to slide in, where one then preheated the various materials and

could then deform them when they were warm. Then, of course, a suitable

silicone membrane was needed so that the membrane does not melt and the

temperature can be withstood.

And so it developed step by step. Of course,

the main memory I have of it is driving from carpenter to carpenter.

That was impressive because that was obviously

most of the time. The invention does not take the most time, selling takes most

of the time. Then you have something that you are convinced of, but then you

have to sell it. So you have to go to the customers and convince them. Then I

went to the fairs, many fairs. It was very interesting. And so it continued to

develop. Exactly. That was the vacuum press story.

Now it's “Columbus”, thanks to your initiative

and thanks to your commitment, with which you have continued. Now I can look at

it with pride and say, “great”, it turned out well and it has continued.

Ruth Koppenberger:

Thank you, thank you. Thank you so much for

sharing your memories. It was really wonderful.

Günther Vetter:

With pleasure. Thank you.

Request offer for COLUMBUS 360°

IMPORTANT: We respond to every inquiry promptly. If you don't hear from us, please check your spam folder or contact us!

Request offer

We will be happy to make you an offer exactly for your individual needs!

Thank you very much for your inquiry!

We will get back in touch with you.

We will get back in touch with you.

INTERESTING BLOG ARTICLE

From rounding to ordering

How to strategically use the interior design trend

Feel the musice

Magnus Hoffmann has developed something particularly creative

Realising Visions

Swiss Precision Meets Creative Design

Tailor-made perfection in Estonia

Haapsalu Uksetehase AS Manufactures Doors for Hampton by Hilton

Premium Interior Fittings and Yacht Furnishings

A Vacuum Press has supported Der Ernzerhof for many years

Outstanding Shopfitting with Vacuum

"außerdem" utilizes the advantages of a vacuum press by Columbus

Flat veneering with vacuum

The use of a vacuum press as a veneer press

Masterful craftsmanship

The Wardrobe for the Master Carpenter Exam

“It presses both flat and curved shapes”

Clairhout Interieur: A Revolution in Interior Design

Columbus customer creates artistic masterpiece

Advertisement for Jean Paul Gaultier in Santiago de Chile

Beautiful Gift Idea

My Esel – exceptional bicycles & e-bikes

Curving the Impossible

Interwood Pushes Design Boundaries with the Columbus Vacuum Press

Infinity for bimobil motorhomes

Large-scale perfection, because high-gloss paint is unforgiving

Precession and art from vacuum

Ziegler creates impressive eye model for the university clinic

From Very Small to Very Large

The Diversity of Applications of a Vacuum Press

The Columbus Pressure Shifting Tool

Natural rubber bends steel

Kempa from Belgium invests in 2 vacuum presses

Round and curved shapes are particularly popular in interior design

the patented modular system

Everyone said it doesn't work - I believed in it

Mold making for mold gluing with vacuum

Practical tips and tricks

Thank you, dad

for the big things, but also for so many small ones

Skateboard ramps with the vacuum press Pioneer

Andreas Schützenberger does great things around the world

Protect your employees and your company

training for PUR hot melt adhesives

ZOSIA by Robert Nößler

His masterpiece with nostalgia and a hidden secret

Why a vacuum press?

You can use it not only to cover curved workpieces...

Fair in May 2023

LIGNA in Hanover

Modern Drop - The masterpiece by Lars Hackl

With vacuum layer gluing and vacuum veneering to natural elegance

Off to new shores with Tommy Kairat's masterpiece

First-class form veneering with the Vacuflex Vacuum Bag

Solid surface materials

Unleash the full potential with a vacuum press

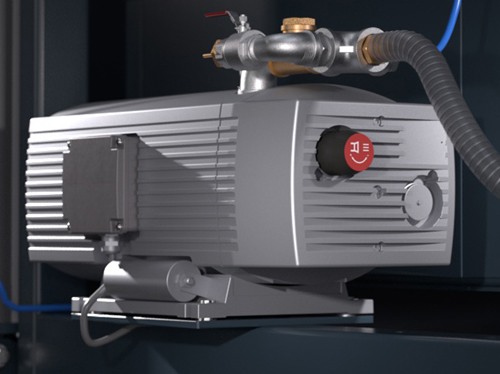

Vacuum pumps

Columbus shows the advantages of dry runners

Free creativity in the creating process

Students from the Freie Waldorfschule Mainz create truly unique items using vacuum technology

1.5 weeks instead of 6 weeks production time

Curved fronts on DALI speakers made in a vacuum press

Markus Kramer's masterpiece

His vision brings the French past into the present

That was the Holz-Handwerk 2022

Spectacular success at the trade fair with the live presentation of PIONEER and MOVE.

The magic is in the details

LL Installations creates high-quality accents in a foyer with Corian

Handmade speakers from Denmark

Customer DALI delights over a million customers in over 70 countries with handcrafted loudspeakers.

Columbus & University of Stuttgart

Innovation meets science!

More success through independence from suppliers

6 reasons for a vacuum press

Beyond all dimensions

Flexstone manufactures large boat parts with INFINITY

Feel the musice

Magnus Hoffmann has developed something particularly creative

Excellence as far as the eye can see

Acoustic panels for the Leonardian Center in Australia

A dazzling cooperation between two pioneers

Vacuum technology. Acrylic glass. Unlimited possibilities.

Individual. Exceptional. Unique.

Best performance with batch size 1

Resysta - A compound better than wood

Design meets sustainability

White River by Jannik Otte

Masterpiece as an eye-catcher for the entrance area

Young creativity

Students - not carpenters!

Full speed ahead with Vacuplus

The tour buses of the world's greatest stars

World premiere: acrylic glass chair

Customer Zöllner manufactures for Acrylic Couture

Columbus makes the impossible possible

VIDEO: Seamless veneering in just a few working steps

Columbus forms Kerrock in Belgium

An exceptional design future

Prager manufactures for Siemens

An innovative trade fair booth

New times bring new opportunities.

How to conquer existing markets by using new applications and materials.

That was the Holz 2019

Columbus and the great Swiss carpenters

Cooperation with Schachermayer

Columbus receives another strong partner

People talk about Columbus

What is published in professional circles about us

MEETING POINT NOBLE VENEER

Visiting the Schachermayer company

Success through vacuum technology

A chili produced with vacuum

Customer Story

Hymer

Customer Story

North German Broadcasting works with Columbus

Columbus Story

Why Columbus?