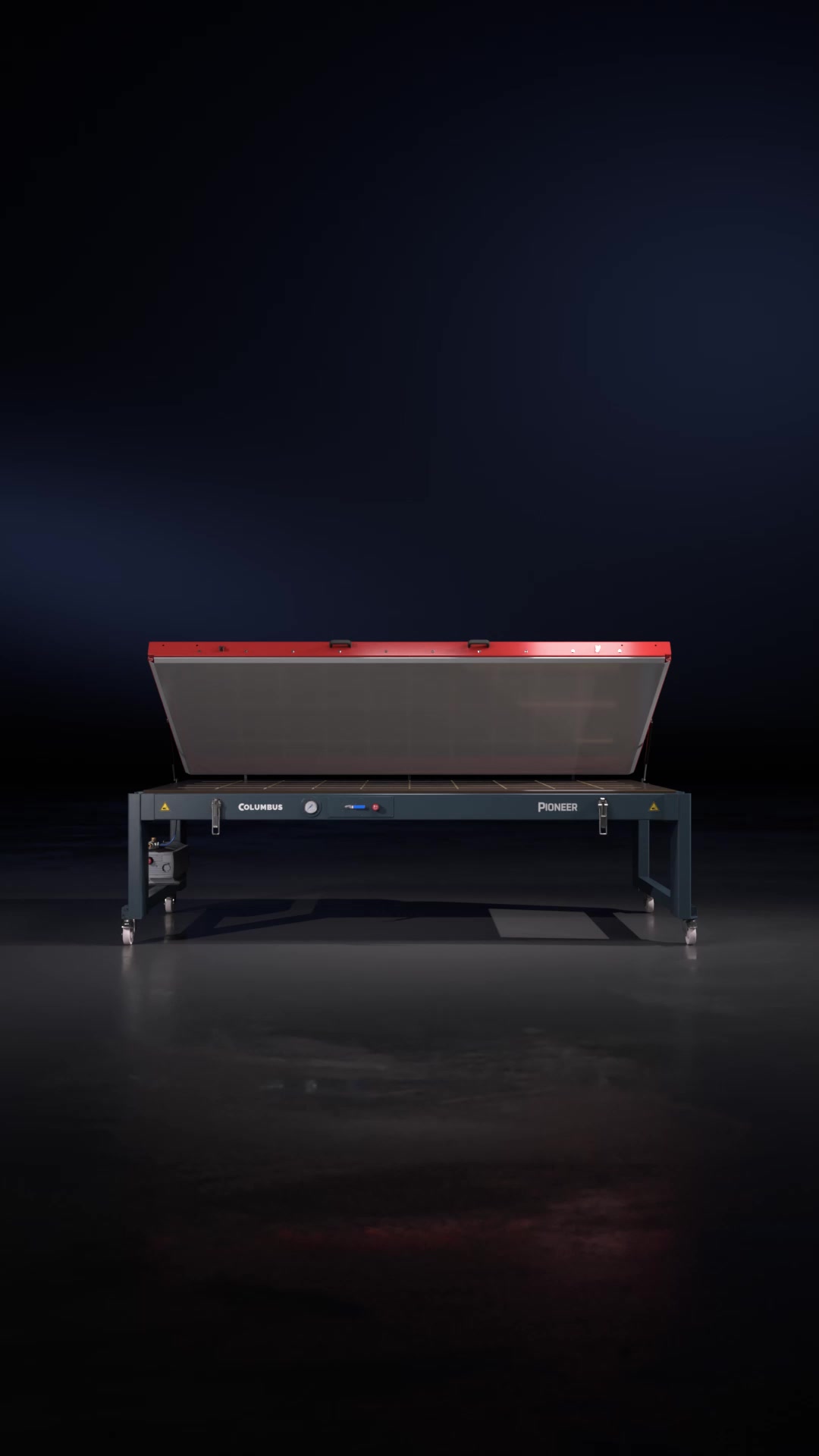

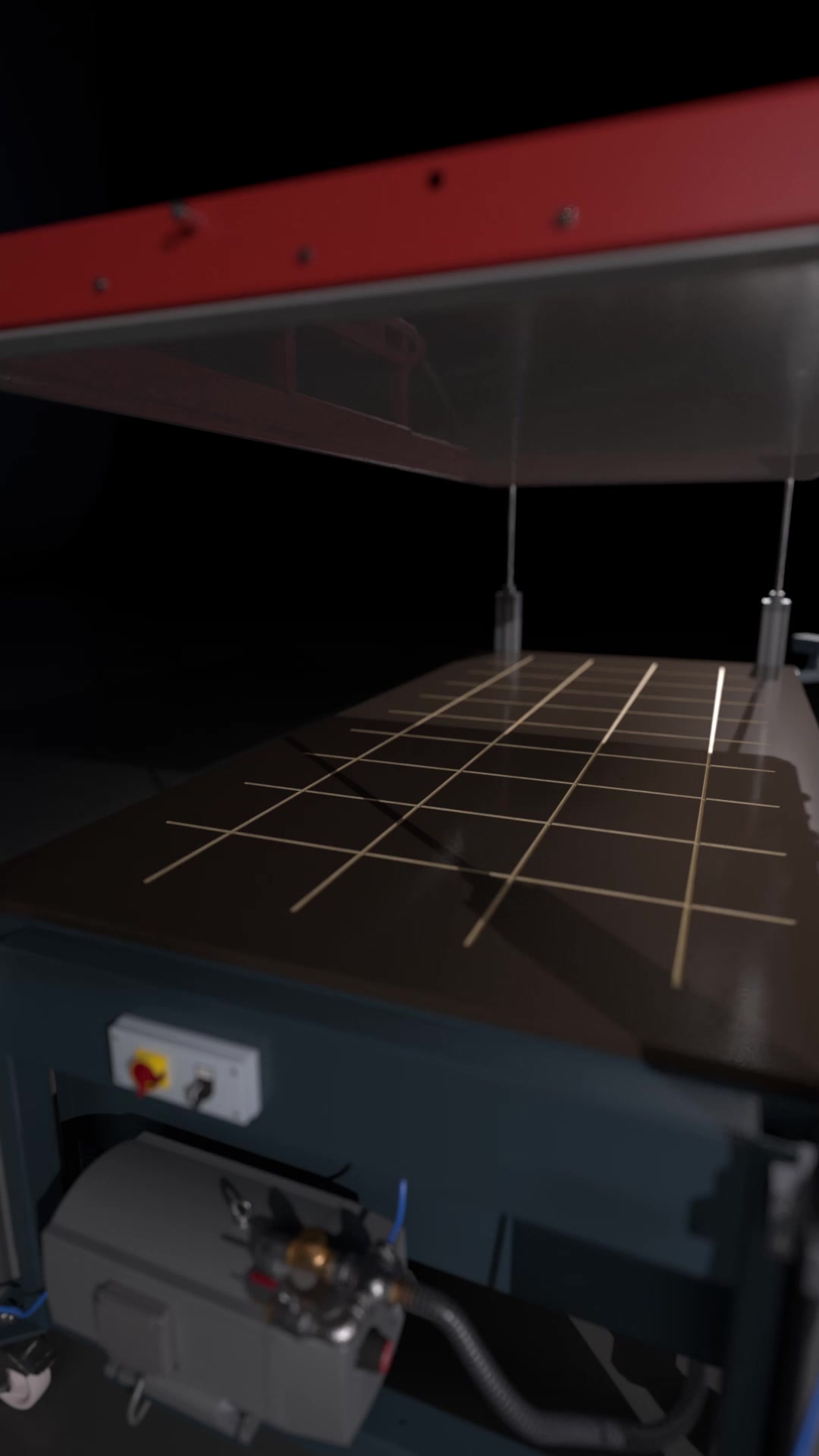

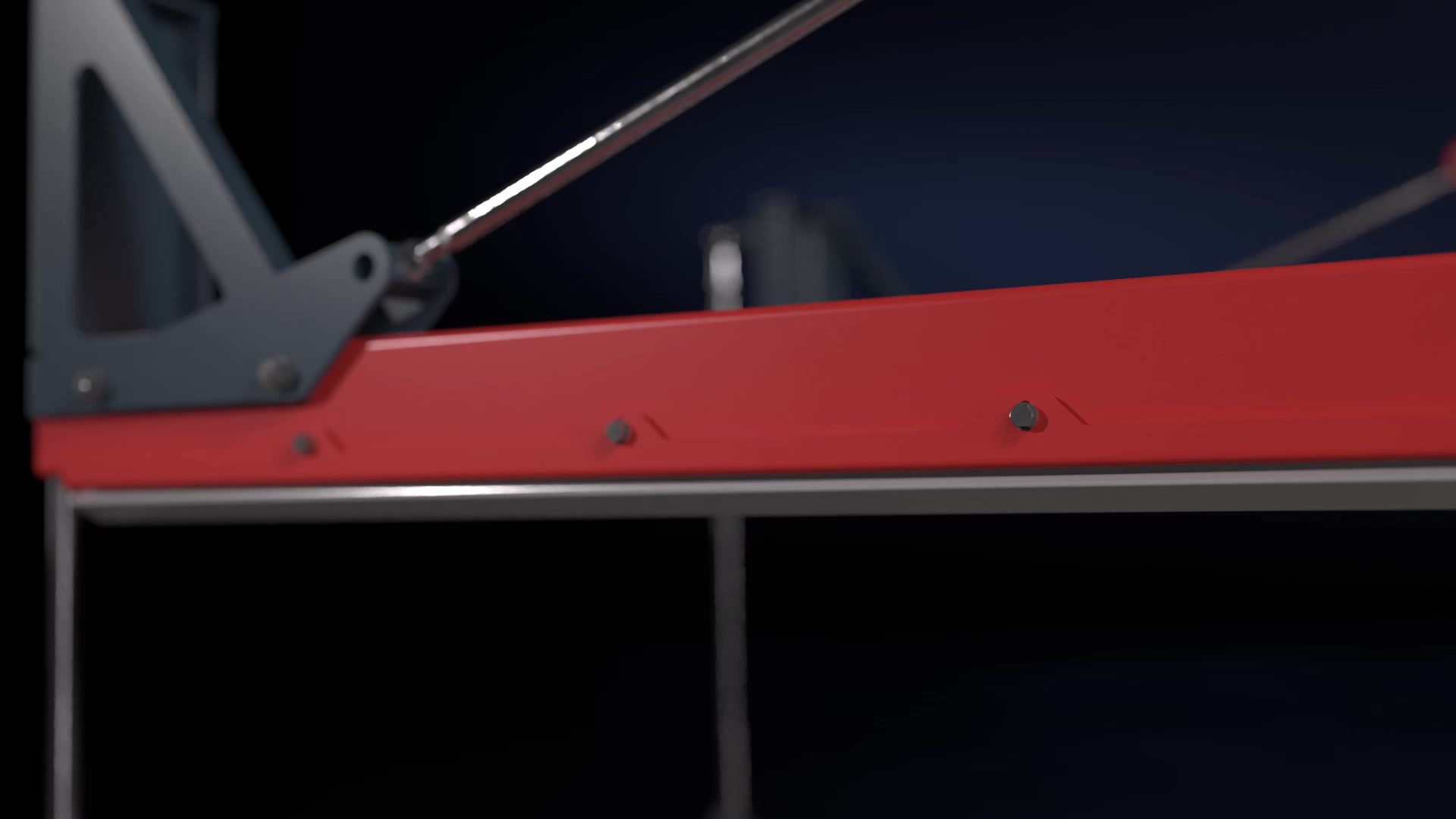

PIONEER is the world‘s first patented vacuum press modular system. Together with his user, it is leading the way in a new era of modern wood and plastic processing.

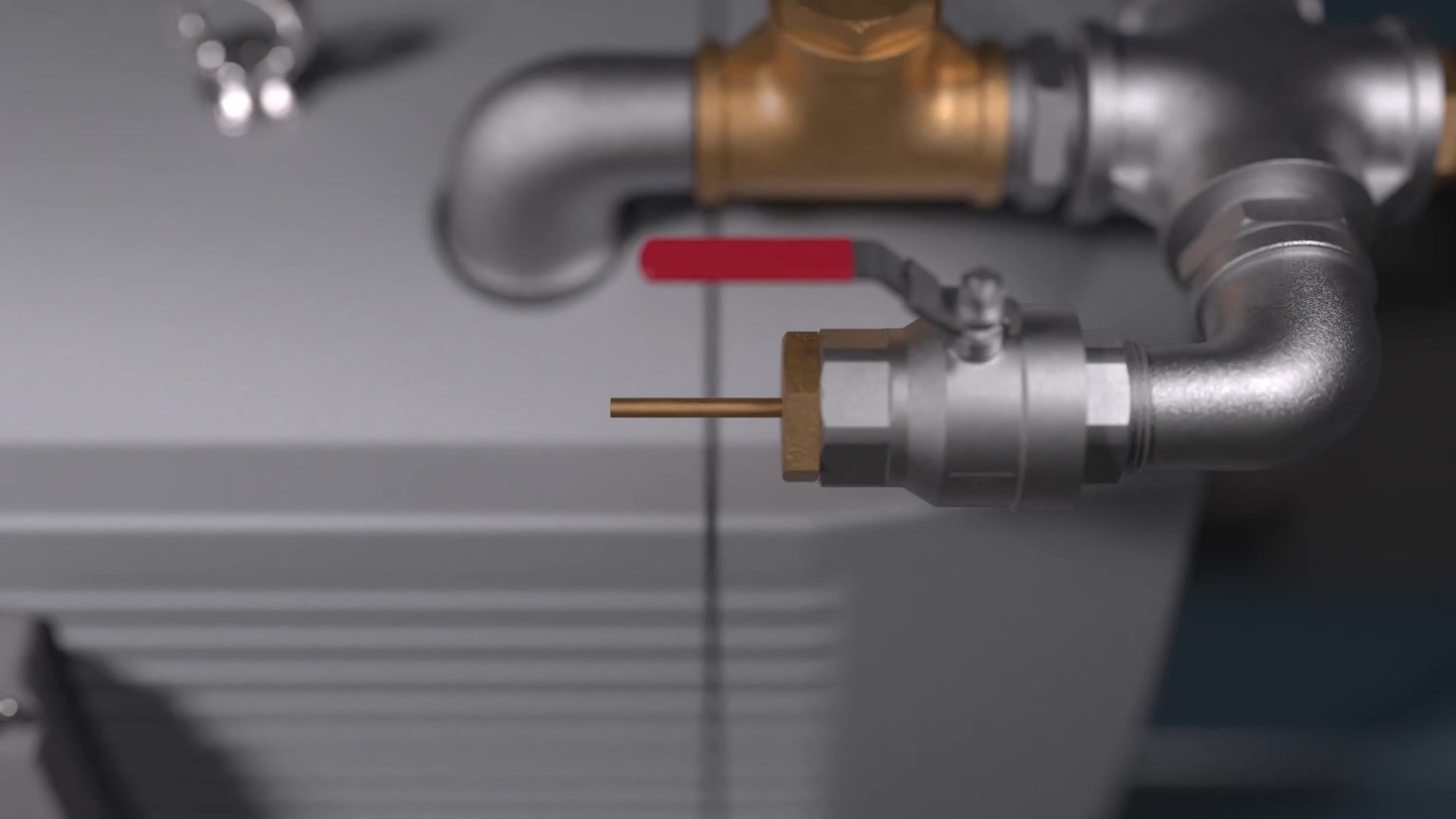

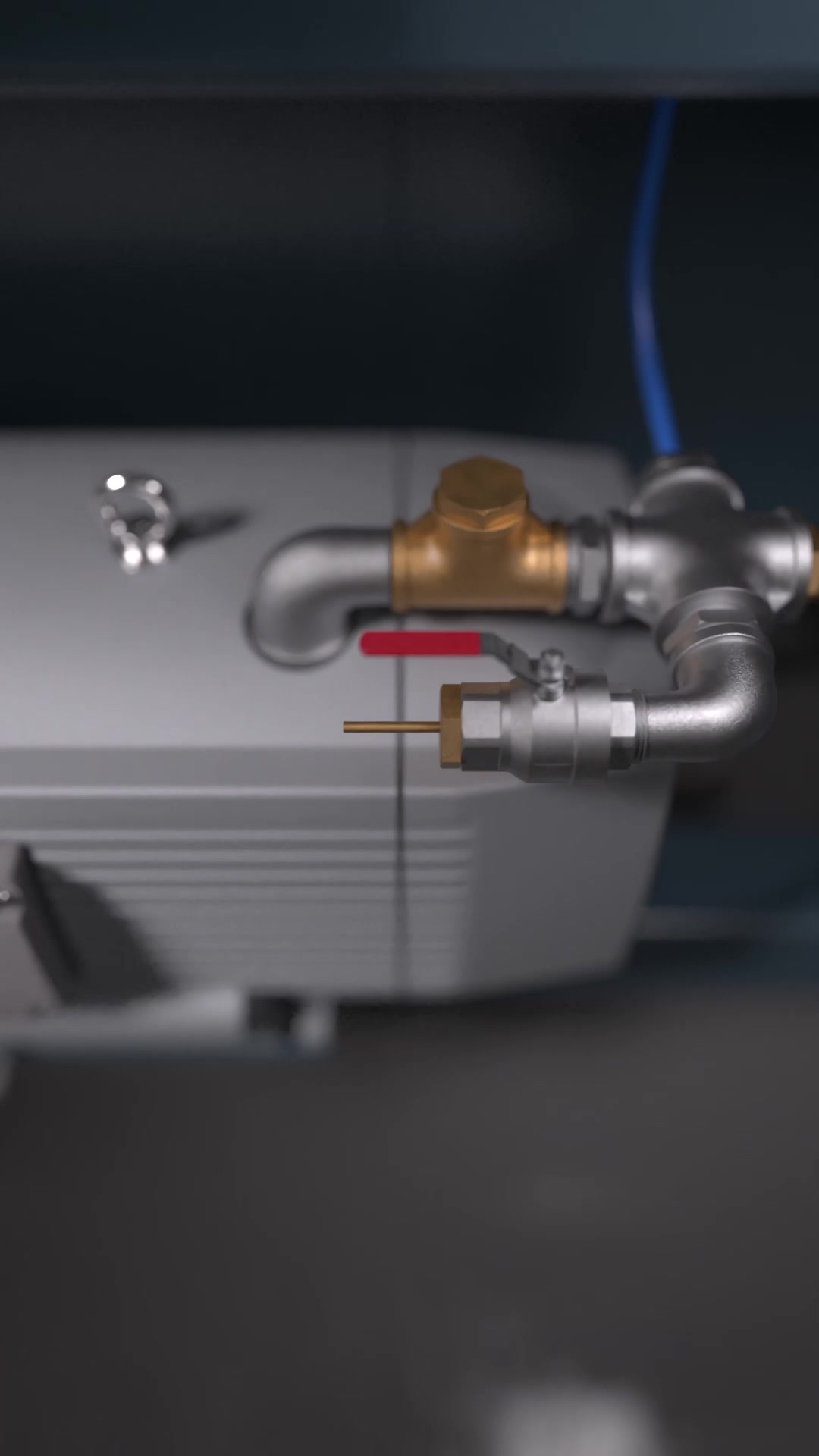

It was designed with the practical experience from over 40 years of innovation leadership and it was perfected with regard to future challenges. The result of the years of development work convinces with the innovative possibilities, the flexibility to be able to react to new requirements at any time as well as with high efficiency. A machine as the basis for sustainable success. It offers production companies everything to create extraordinary workpieces in the future, to delight customers with new things and to increase sales.

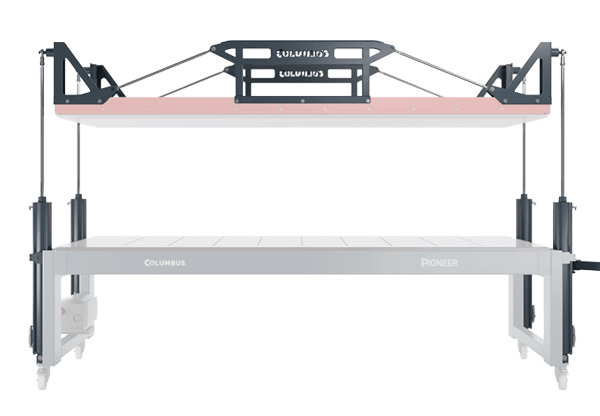

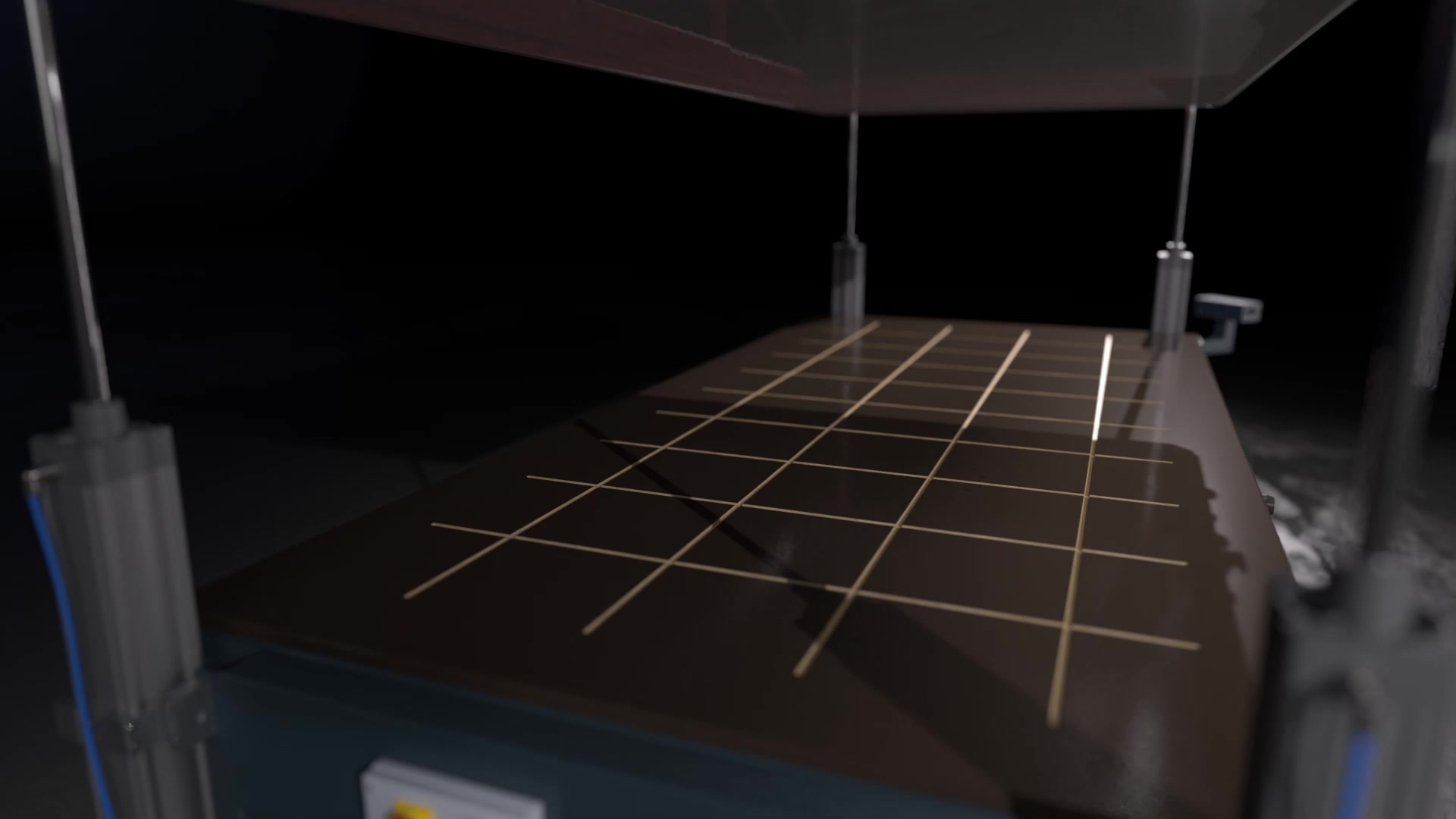

The world‘s first patented modular design — based on a high-precision vacuum press — makes it a partner for many decades and guarantees high investment security. The sophisticated design enables users to add all expansion modules subsequently and independently, in order to flexibly expand the variety of applications and the production spectrum according to own requirements.