Unleash the full potential with a vacuum press

Solid surface materials are true miracle materials that offer craft businesses almost limitless possibilities in terms of areas of application and processing options. A vacuum press is the best tool for users to fully take advantage of the materials potential.

Solid surface materials basically consist of polyester resin or acrylic resin as well as set natural materials such as aluminum trihydrate. Together, these components result in a non-porous, easy-care polymerized surface material that consists of a single mass. Its homogeneous structure makes it particularly versatile.

For users of a vacuum press, acrylic resin-bonded solid surface materials are of particular interest, as these – in contrast to polyester-bonded solid surface materials – can be thermally deformed particularly well.

Solid surface materials score with an enormous number of advantages, of which, depending on the application, always a different one comes first. As already mentioned, solid surface materials are ideal for deforming. No matter what they are used for, they find a versatile optical or functional task in every environment.

The material composition and quality bring several advantages. On the one hand solid surface materials are solid, very robust and extremely scratch, impact and wear resistant. They still inspire optically even after years. Due to the UV resistance also in the outdoor area. In addition, the material has a homogeneous structure. If scratches or damage should occur due to incorrect treatment, they can usually be easily sanded down and polished out. This homogeneity leads us straight to a very special and decisive advantage. Solid surface materials are non-porous. This, coupled with the possibility of being able to glue them completely seamlessly, results in a particularly hygienic surface that lasts a long time and is particularly easy to clean. Moisture cannot penetrate and bacteria and mold don't stand a chance. Solid surface materials are therefore suitable for both indoor and outdoor applications and wherever hygiene is a top priority. In addition, the material is particularly sustainable, recyclable and also ideal for allergy sufferers.

Solid surface materials are used in all shapes and colors, in bathrooms, kitchens, hospitals, laboratories, but also in numerous outdoor applications. Some transparent materials can even be backlit.

As already mentioned, vacuum presses offer the ideal opportunity to process solid surface materials. A vacuum press from Columbus allows its user to bring the solid surface material into many desired shapes.

The smooth and highly elastic membrane – heat-resistant up to +230° C – allows an extremely material-friendly processing without pressure points or scratches - even with a maximum pressure of 9t/m2 - because it adapts perfectly.

To heat up the material, Columbus has developed an external high-performance heating system, which is available in modular form. This can easily be placed under the vacuum table to save space.

When processing mineral materials, the thermal treatment before pressing is a critical factor. For this reason, Columbus deliberately installed a circulating air heating system. In contrast to conventional heating plates, which are not only very expensive and can often cause discoloration, especially with light-colored materials, a circulating air system guarantees very even, gentle heating. The large support surface with grating completes the system.

What are solid surface materials?

Solid surface materials basically consist of polyester resin or acrylic resin as well as set natural materials such as aluminum trihydrate. Together, these components result in a non-porous, easy-care polymerized surface material that consists of a single mass. Its homogeneous structure makes it particularly versatile.

For users of a vacuum press, acrylic resin-bonded solid surface materials are of particular interest, as these – in contrast to polyester-bonded solid surface materials – can be thermally deformed particularly well.

Properties and advantages of solid surface materials?

Solid surface materials score with an enormous number of advantages, of which, depending on the application, always a different one comes first. As already mentioned, solid surface materials are ideal for deforming. No matter what they are used for, they find a versatile optical or functional task in every environment.

The material composition and quality bring several advantages. On the one hand solid surface materials are solid, very robust and extremely scratch, impact and wear resistant. They still inspire optically even after years. Due to the UV resistance also in the outdoor area. In addition, the material has a homogeneous structure. If scratches or damage should occur due to incorrect treatment, they can usually be easily sanded down and polished out. This homogeneity leads us straight to a very special and decisive advantage. Solid surface materials are non-porous. This, coupled with the possibility of being able to glue them completely seamlessly, results in a particularly hygienic surface that lasts a long time and is particularly easy to clean. Moisture cannot penetrate and bacteria and mold don't stand a chance. Solid surface materials are therefore suitable for both indoor and outdoor applications and wherever hygiene is a top priority. In addition, the material is particularly sustainable, recyclable and also ideal for allergy sufferers.

Areas of application for solid surface material

Solid surface materials are used in all shapes and colors, in bathrooms, kitchens, hospitals, laboratories, but also in numerous outdoor applications. Some transparent materials can even be backlit.

Optimal processing using a vacuum press

As already mentioned, vacuum presses offer the ideal opportunity to process solid surface materials. A vacuum press from Columbus allows its user to bring the solid surface material into many desired shapes.

The smooth and highly elastic membrane – heat-resistant up to +230° C – allows an extremely material-friendly processing without pressure points or scratches - even with a maximum pressure of 9t/m2 - because it adapts perfectly.

To heat up the material, Columbus has developed an external high-performance heating system, which is available in modular form. This can easily be placed under the vacuum table to save space.

When processing mineral materials, the thermal treatment before pressing is a critical factor. For this reason, Columbus deliberately installed a circulating air heating system. In contrast to conventional heating plates, which are not only very expensive and can often cause discoloration, especially with light-colored materials, a circulating air system guarantees very even, gentle heating. The large support surface with grating completes the system.

Find out more at Pioneer, the unique vacuum press modular system

Request offer for COLUMBUS 360°

IMPORTANT: We respond to every inquiry promptly. If you don't hear from us, please check your spam folder or contact us!

Request offer

We will be happy to make you an offer exactly for your individual needs!

Thank you very much for your inquiry!

We will get back in touch with you.

We will get back in touch with you.

INTERESTING BLOG ARTICLE

Why I Developed Columbus 360°

50 Years of Columbus – and a System That Changes Everything

Realising Visions

Swiss Precision Meets Creative Design

Tailor-made perfection in Estonia

Haapsalu Uksetehase AS Manufactures Doors for Hampton by Hilton

Premium Interior Fittings and Yacht Furnishings

A Vacuum Press has supported Der Ernzerhof for many years

Outstanding Shopfitting with Vacuum

"außerdem" utilizes the advantages of a vacuum press by Columbus

Flat veneering with vacuum

The use of a vacuum press as a veneer press

Masterful craftsmanship

The Wardrobe for the Master Carpenter Exam

“It presses both flat and curved shapes”

Clairhout Interieur: A Revolution in Interior Design

Columbus customer creates artistic masterpiece

Advertisement for Jean Paul Gaultier in Santiago de Chile

Beautiful Gift Idea

My Esel – exceptional bicycles & e-bikes

Curving the Impossible

Interwood Pushes Design Boundaries with the Columbus Vacuum Press

Infinity for bimobil motorhomes

Large-scale perfection, because high-gloss paint is unforgiving

Precession and art from vacuum

Ziegler creates impressive eye model for the university clinic

From Very Small to Very Large

The Diversity of Applications of a Vacuum Press

The Columbus Pressure Shifting Tool

Natural rubber bends steel

Kempa from Belgium invests in 2 vacuum presses

Round and curved shapes are particularly popular in interior design

the patented modular system

Everyone said it doesn't work - I believed in it

Mold making for mold gluing with vacuum

Practical tips and tricks

Thank you, dad

for the big things, but also for so many small ones

The invention of the Vacuum Bag

Interview with Günther Vetter about the origin of vacuum technology

Skateboard ramps with the vacuum press Pioneer

Andreas Schützenberger does great things around the world

Protect your employees and your company

training for PUR hot melt adhesives

ZOSIA by Robert Nößler

His masterpiece with nostalgia and a hidden secret

Why a vacuum press?

You can use it not only to cover curved workpieces...

Fair in May 2023

LIGNA in Hanover

Modern Drop - The masterpiece by Lars Hackl

With vacuum layer gluing and vacuum veneering to natural elegance

Off to new shores with Tommy Kairat's masterpiece

First-class form veneering with the Vacuflex Vacuum Bag

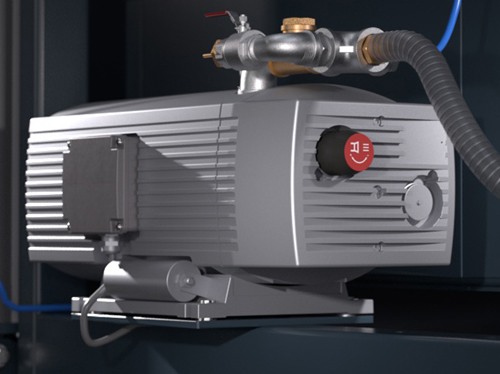

Vacuum pumps

Columbus shows the advantages of dry runners

Free creativity in the creating process

Students from the Freie Waldorfschule Mainz create truly unique items using vacuum technology

1.5 weeks instead of 6 weeks production time

Curved fronts on DALI speakers made in a vacuum press

Markus Kramer's masterpiece

His vision brings the French past into the present

That was the Holz-Handwerk 2022

Spectacular success at the trade fair with the live presentation of PIONEER and MOVE.

The magic is in the details

LL Installations creates high-quality accents in a foyer with Corian

Handmade speakers from Denmark

Customer DALI delights over a million customers in over 70 countries with handcrafted loudspeakers.

Columbus & University of Stuttgart

Innovation meets science!

More success through independence from suppliers

6 reasons for a vacuum press

Beyond all dimensions

Flexstone manufactures large boat parts with INFINITY

Feel the musice

Magnus Hoffmann has developed something particularly creative

Excellence as far as the eye can see

Acoustic panels for the Leonardian Center in Australia

A dazzling cooperation between two pioneers

Vacuum technology. Acrylic glass. Unlimited possibilities.

Individual. Exceptional. Unique.

Best performance with batch size 1

Resysta - A compound better than wood

Design meets sustainability

White River by Jannik Otte

Masterpiece as an eye-catcher for the entrance area

Young creativity

Students - not carpenters!

Full speed ahead with Vacuplus

The tour buses of the world's greatest stars

World premiere: acrylic glass chair

Customer Zöllner manufactures for Acrylic Couture

Columbus makes the impossible possible

VIDEO: Seamless veneering in just a few working steps

Columbus forms Kerrock in Belgium

An exceptional design future

Prager manufactures for Siemens

An innovative trade fair booth

New times bring new opportunities.

How to conquer existing markets by using new applications and materials.

That was the Holz 2019

Columbus and the great Swiss carpenters

Cooperation with Schachermayer

Columbus receives another strong partner

People talk about Columbus

What is published in professional circles about us

MEETING POINT NOBLE VENEER

Visiting the Schachermayer company

Success through vacuum technology

A chili produced with vacuum

Customer Story

Hymer

Customer Story

North German Broadcasting works with Columbus

Columbus Story

Why Columbus?